"You said change management?"

On PC or tablet, immediate appropriation by your operators.

Easy to deploy

1 week of commissioning.

1 single packaged version with all functions included

No development to foresee.

Everything is configurable and parameterisable.

Fast ROI

Return on investment of 6 months (as an indication).

Learn more

The Qual@xy Suite, MES for the factory of the future

Are you committed to continuous improvement of quality, your processes, reduction of non-conformities and costs?

Qual@xy Suite, MES (Manufacturing Execution System) for Industry 4.0, covers the following areas:

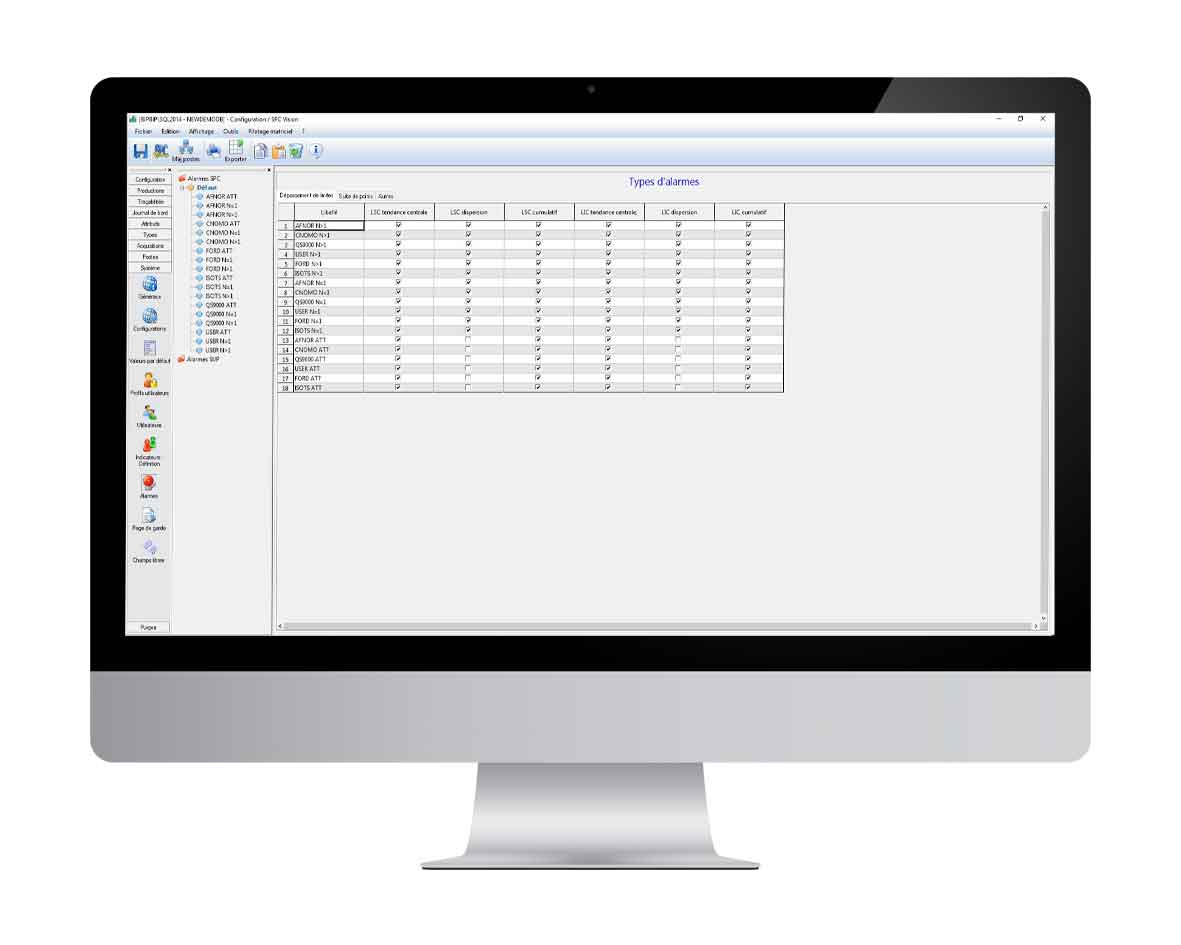

• Measurement management and SPC alarm management

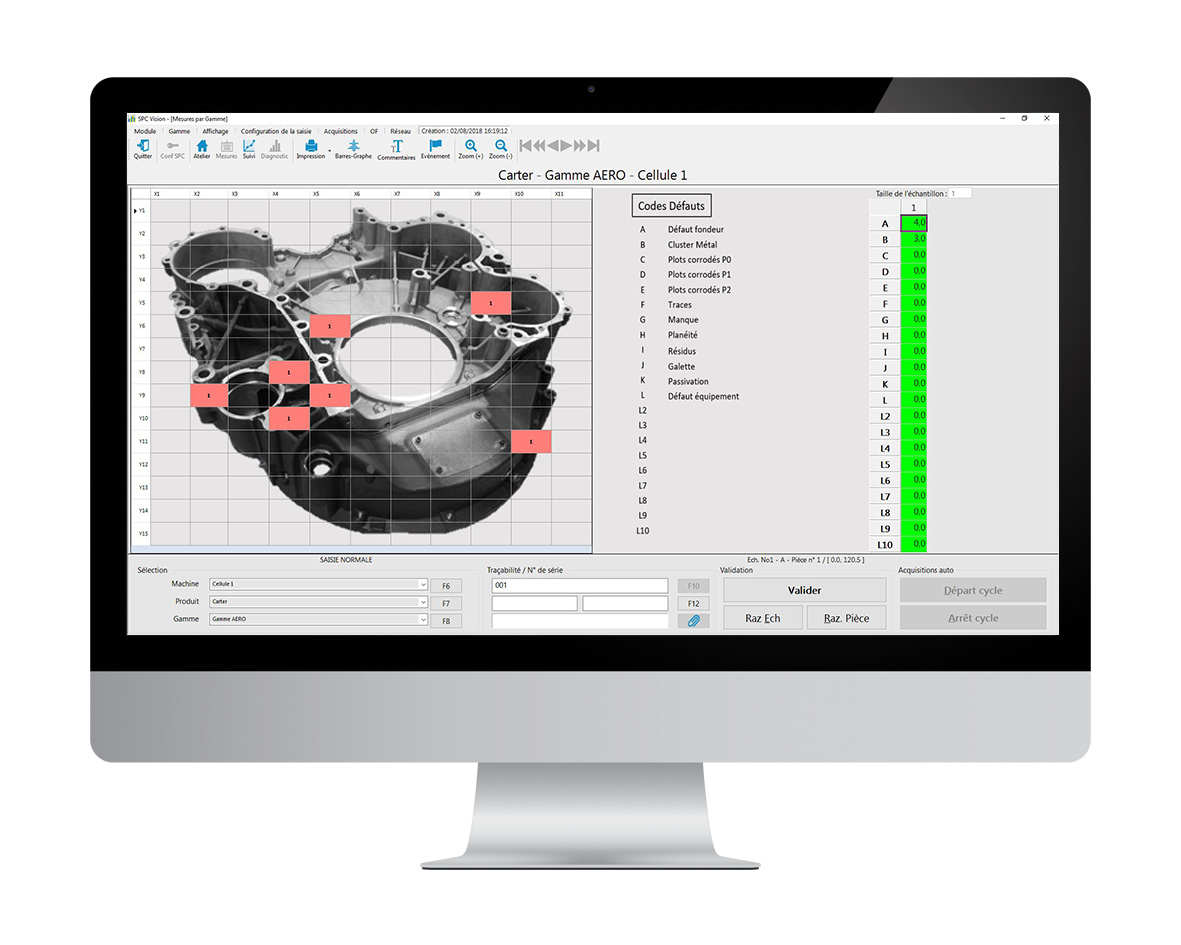

• Part inspection with defect mapping

• Supplier quality control

• Integrated reporting and statistical analysis

• Electronic and interactive work instructions

• Integrated traceability

• Performance analysis, quality and productivity dashboards

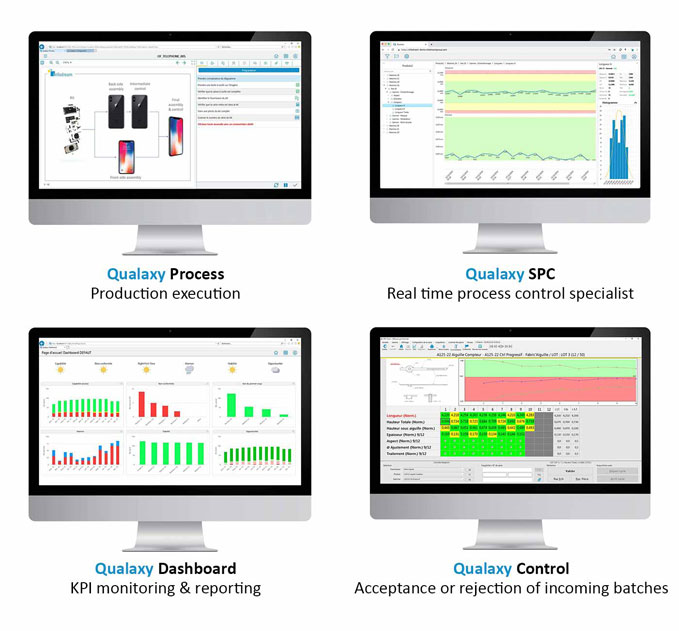

4 modules to improve quality and productivity

"You said change management?"

On PC or tablet, immediate appropriation by your operators.

Easy to deploy

1 week of commissioning.

1 single packaged version with all functions included

No development to foresee.

Everything is configurable and parameterisable.

Fast ROI

Return on investment of 6 months

(as an indication).

Learn more

The Qual@xy Suite, MES for the factory of the future

Are you committed to continuous improvement of quality, your processes, reduction of non-conformities and costs?

Qual@xy Suite, MES (Manufacturing Execution System) for Industry 4.0, covers the following areas:

• Measurement management and SPC alarm management

• Part inspection with defect mapping

• Supplier quality control

• Integrated reporting and statistical analysis

• Electronic and interactive work instructions

• Integrated traceability

• Performance analysis, quality and productivity dashboards

4 modules to improve quality and productivity

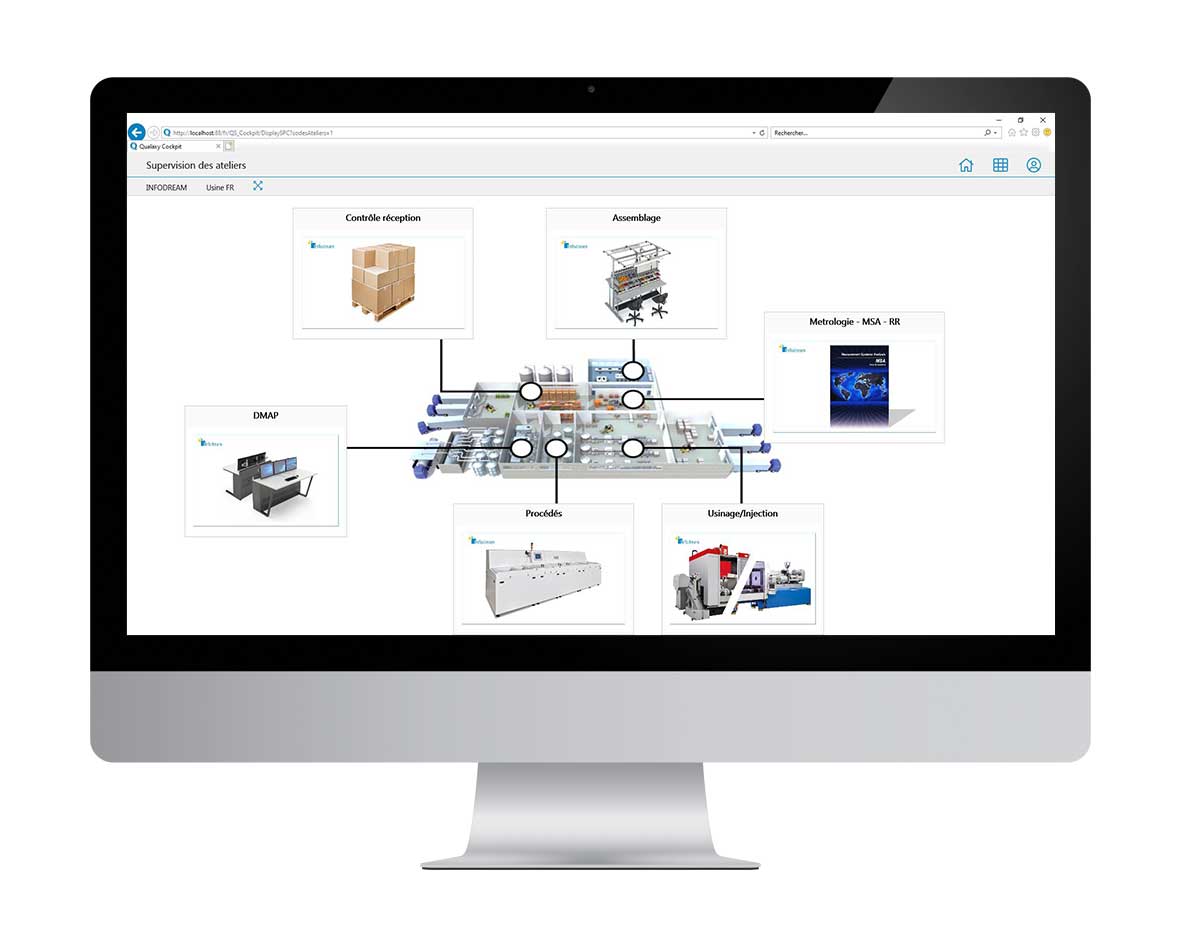

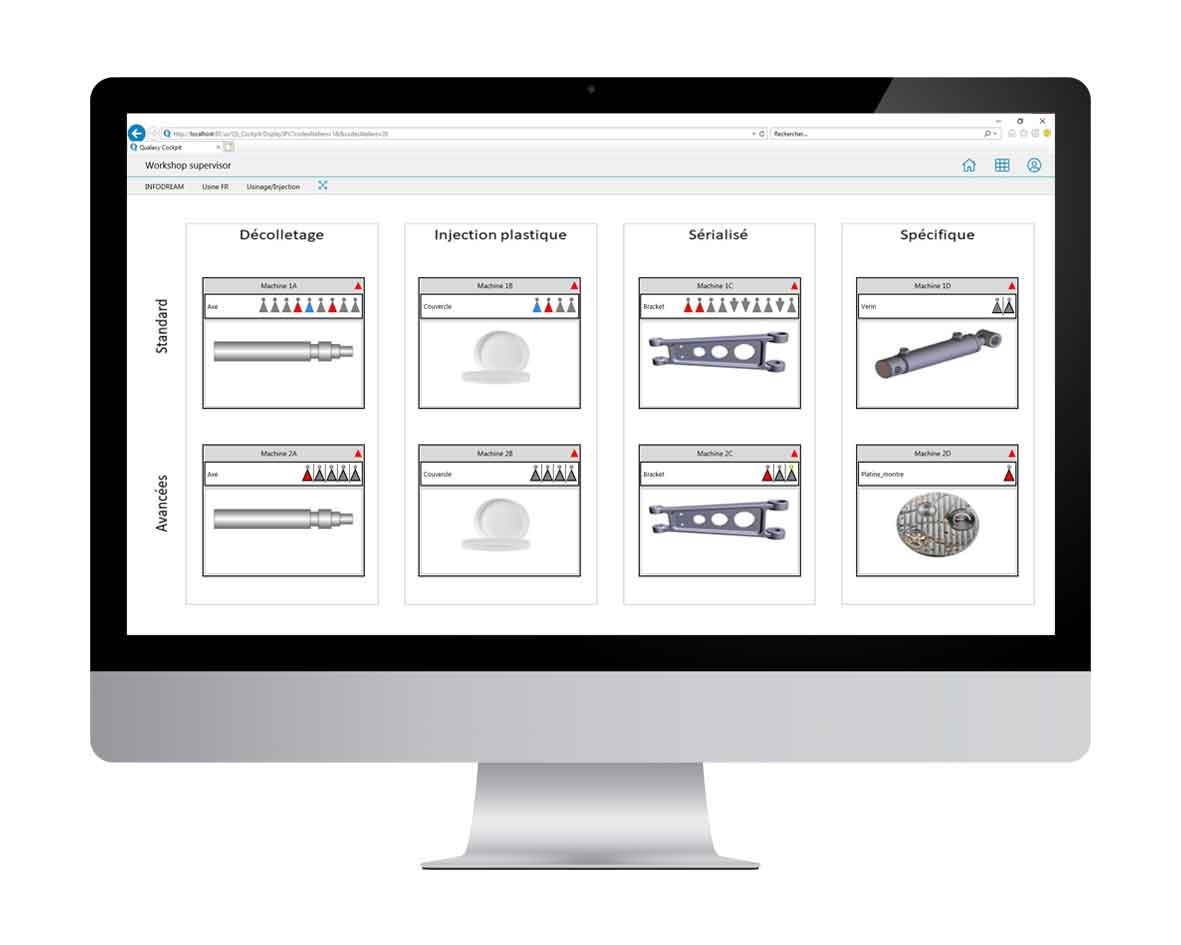

Qualaxy Process

the paperless workshop

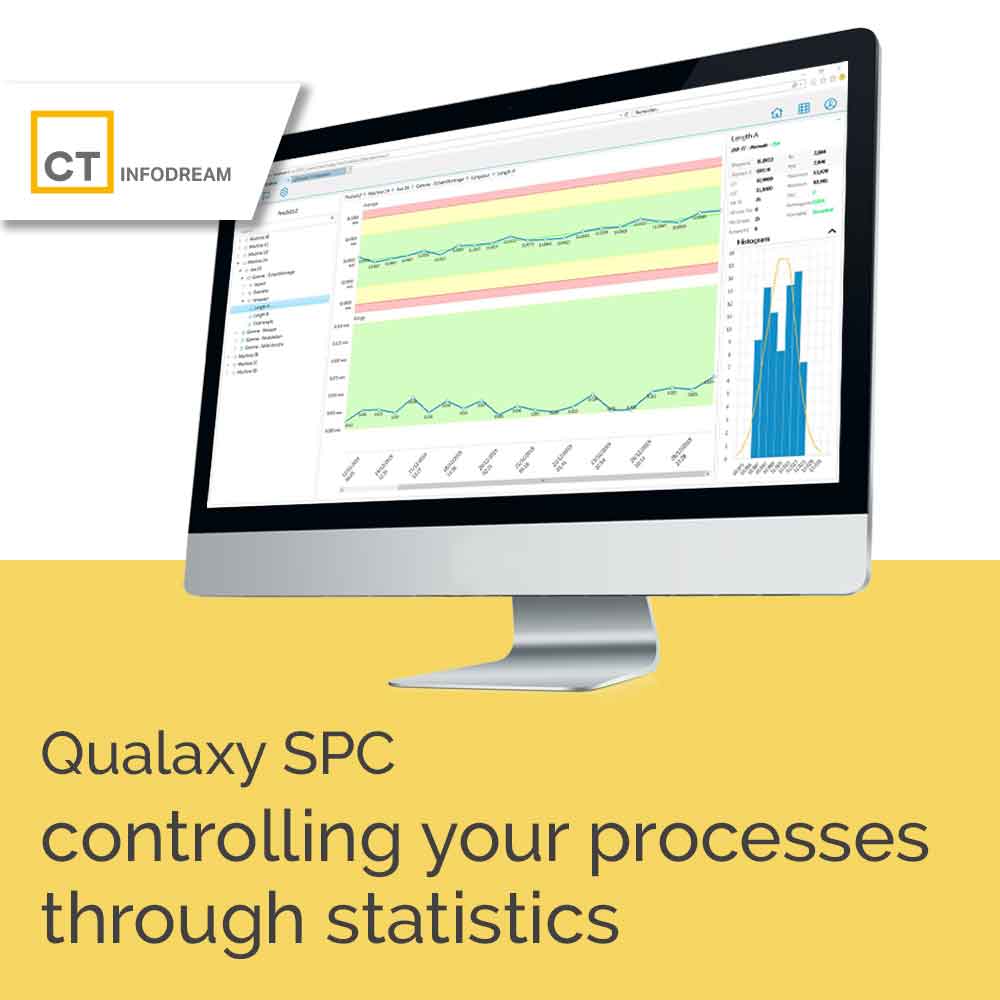

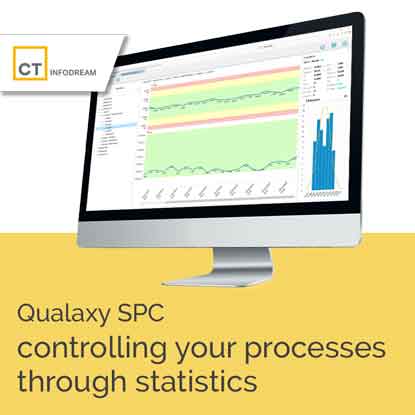

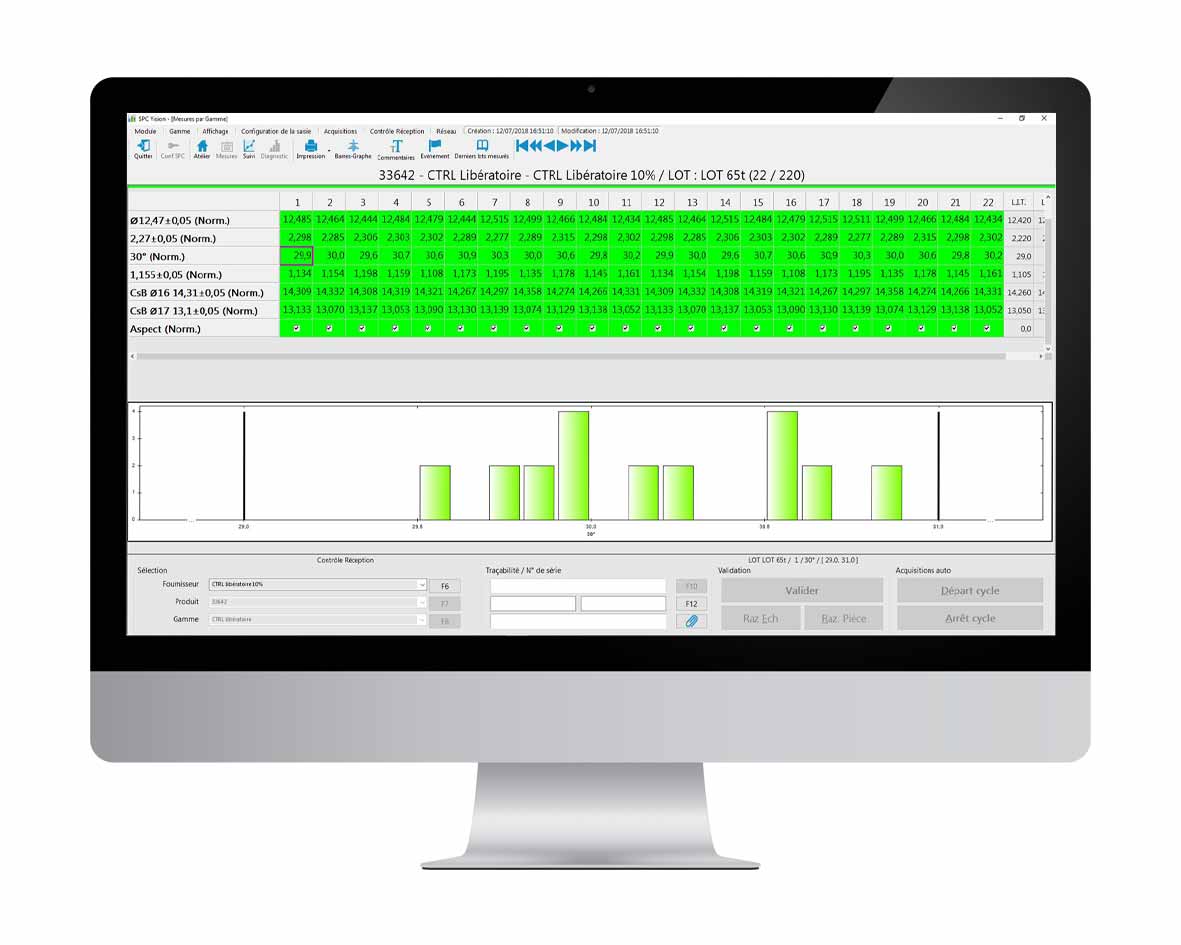

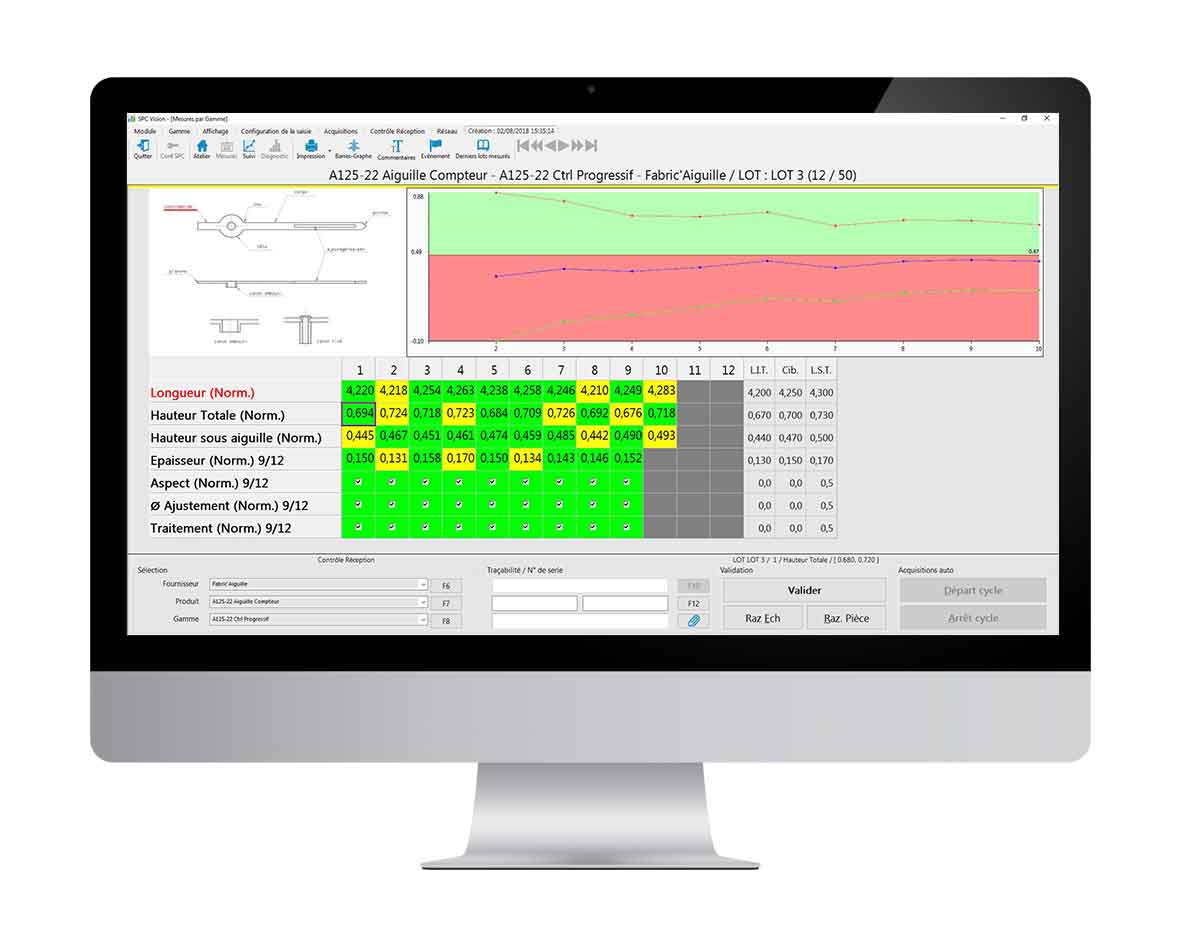

Qualaxy SPC

controlling your processes through statistics (SPC)

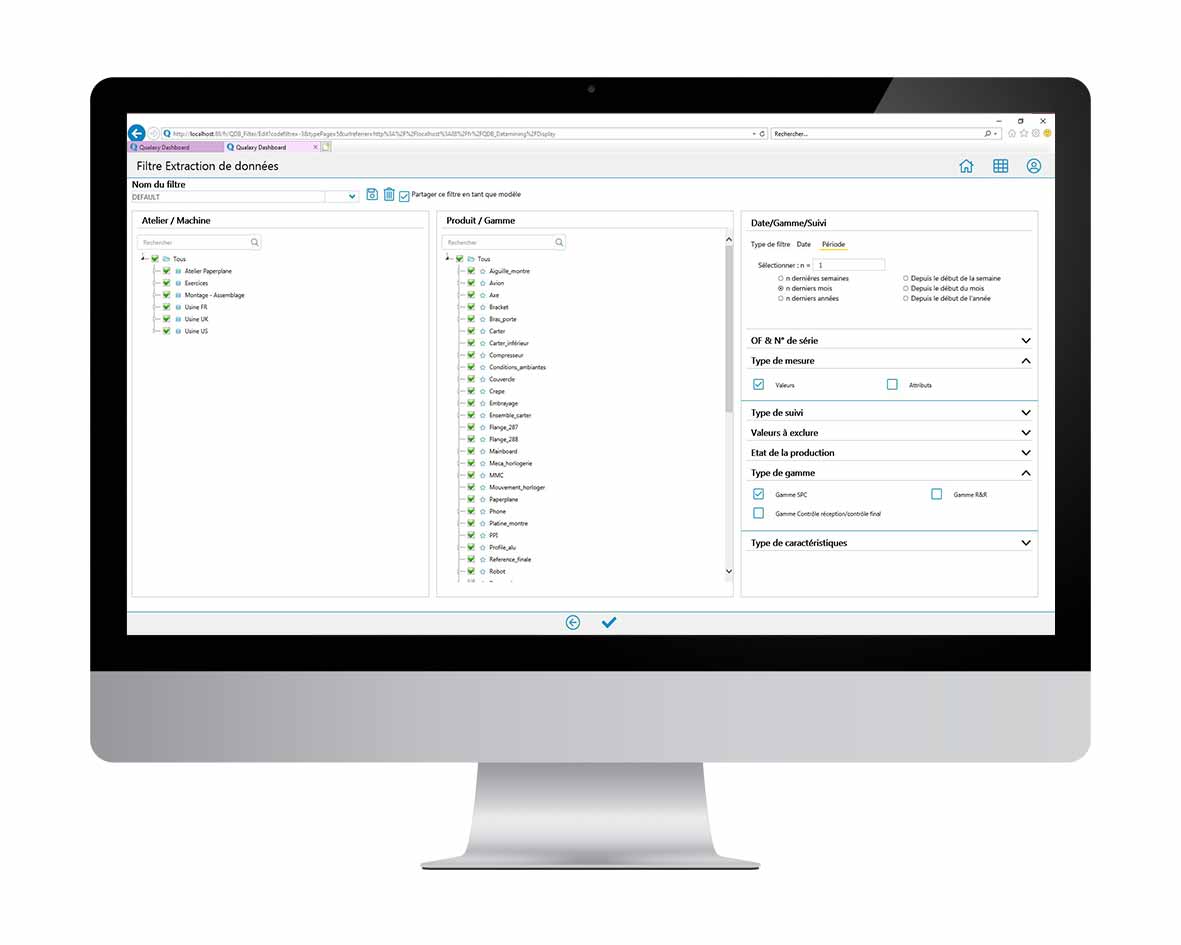

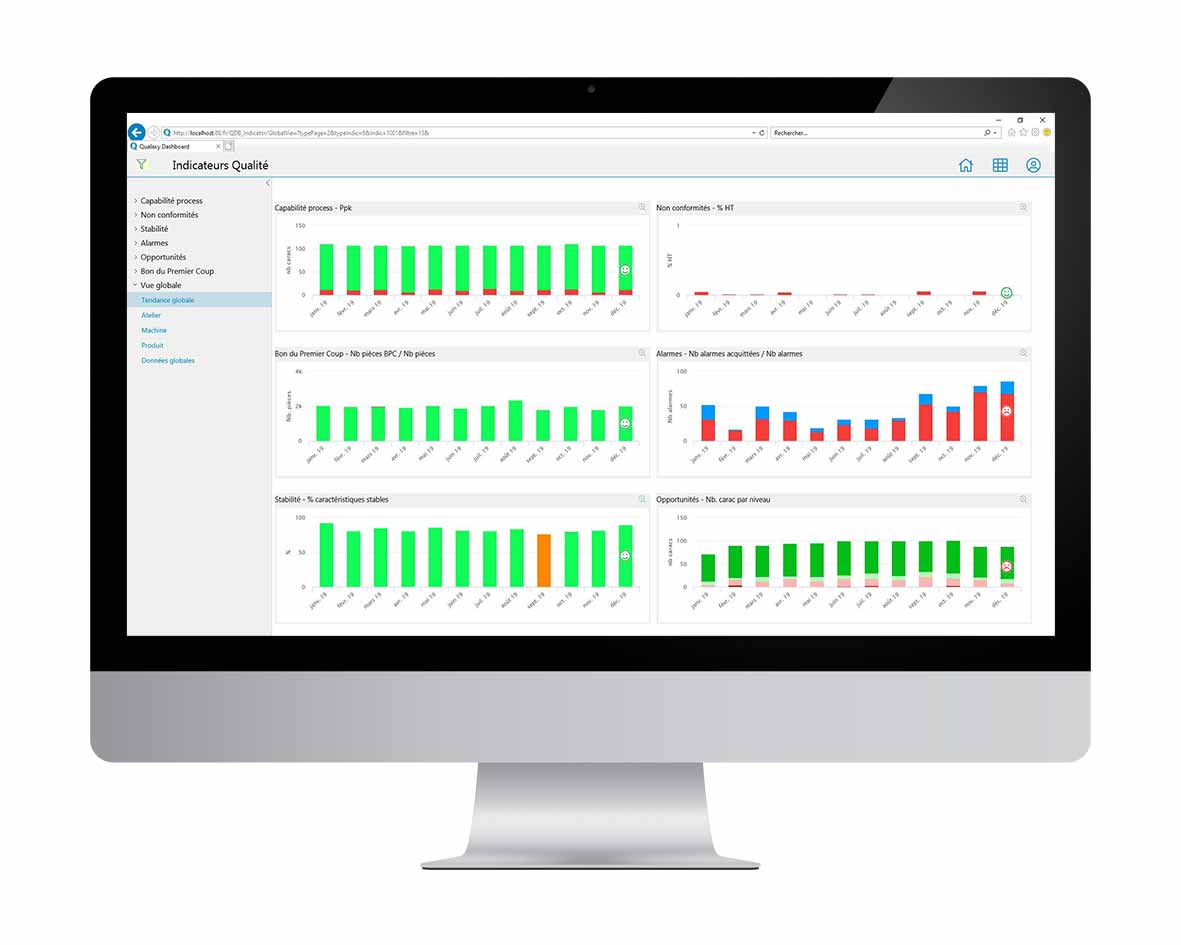

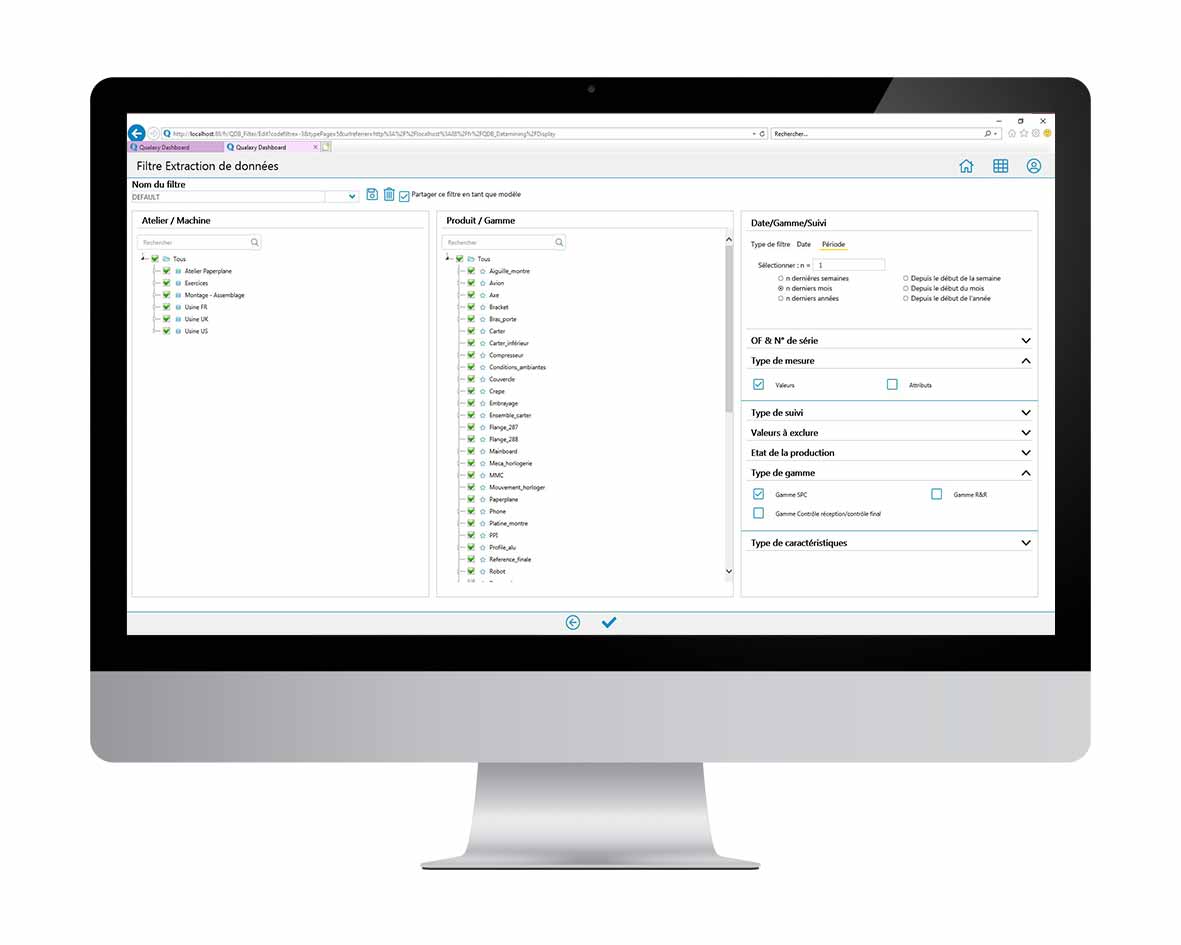

Qualaxy Dashboard

analysing and visualising the performance of your workshop

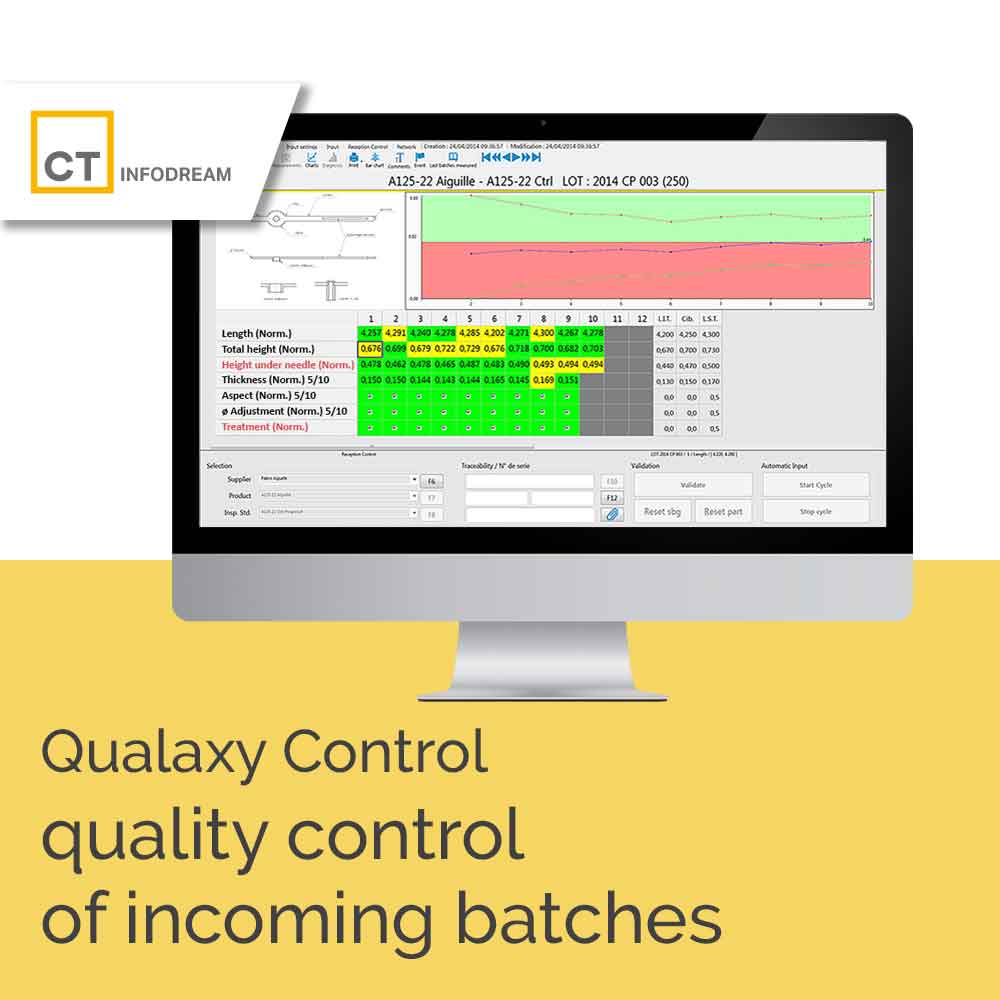

Qualaxy Control

to optimise the quality of your incoming batches

Paperless workshop

And therefore zero constraints! Your operators are finally guided by interactive work instructions.

"Where is this Work order ?"

Instant response from the shop floor, progress synchronised in real time with your ERP. A real time-saver!

Monitoring your production is good. In real time, it's better.

No more hunting for information. You know at all times where your production orders stand.

Learn more

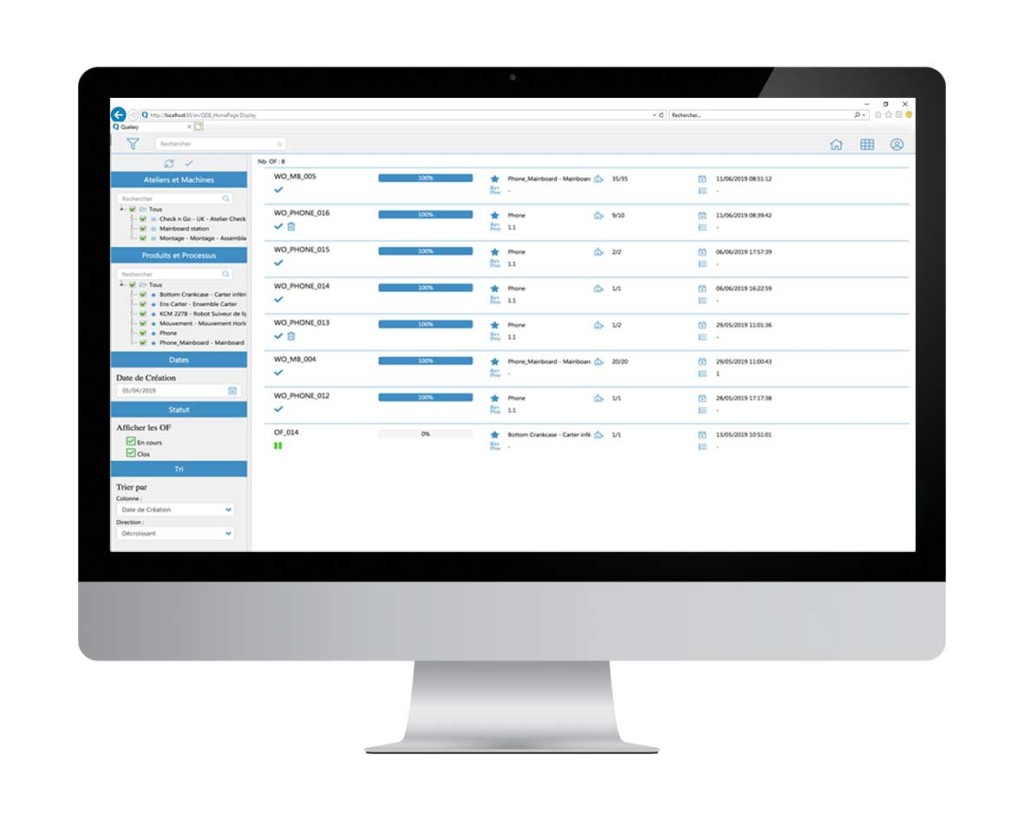

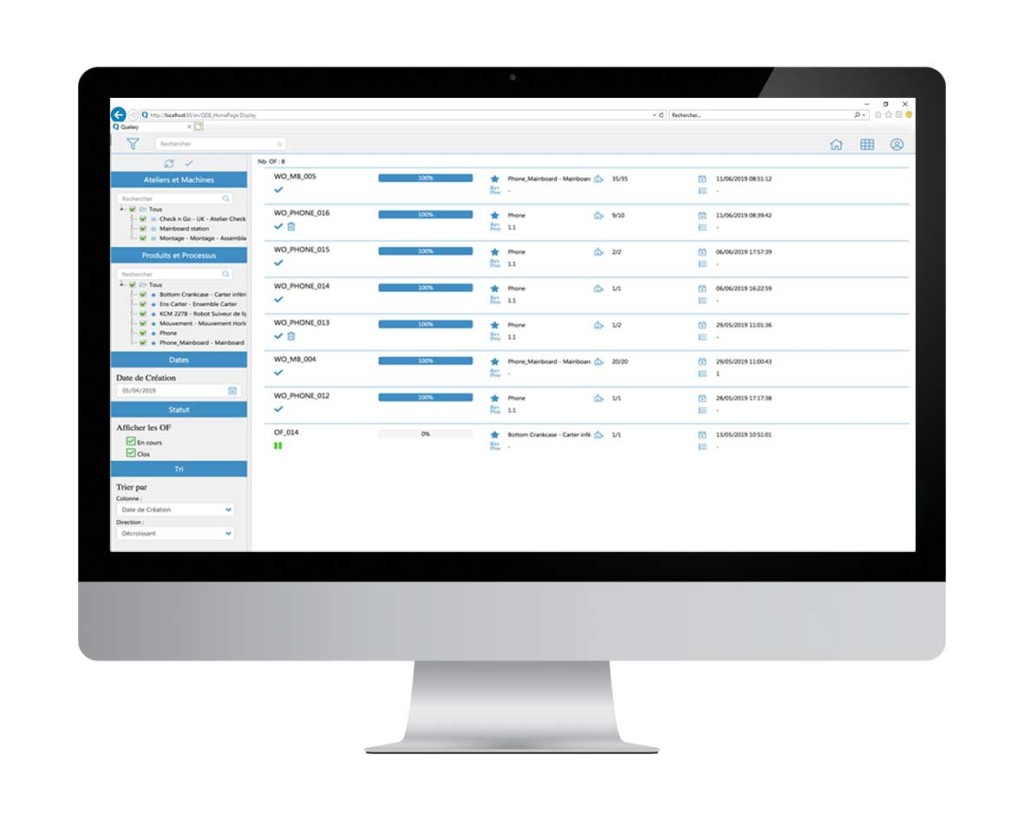

1. Management and traceability of WOs

No more need to go through the workshop to find out the status of a WO. With Qual@xy Process, you benefit from remote monitoring of the process : progress of your WO’s, their current status, the estimated time remaining and any unforeseen deviations.

If the WO is interrupted, a cause of interruption must be entered by the operator, allowing analysis of the causes and duration of the interruption.

All data is centralised, consolidated, shared and available in real time.

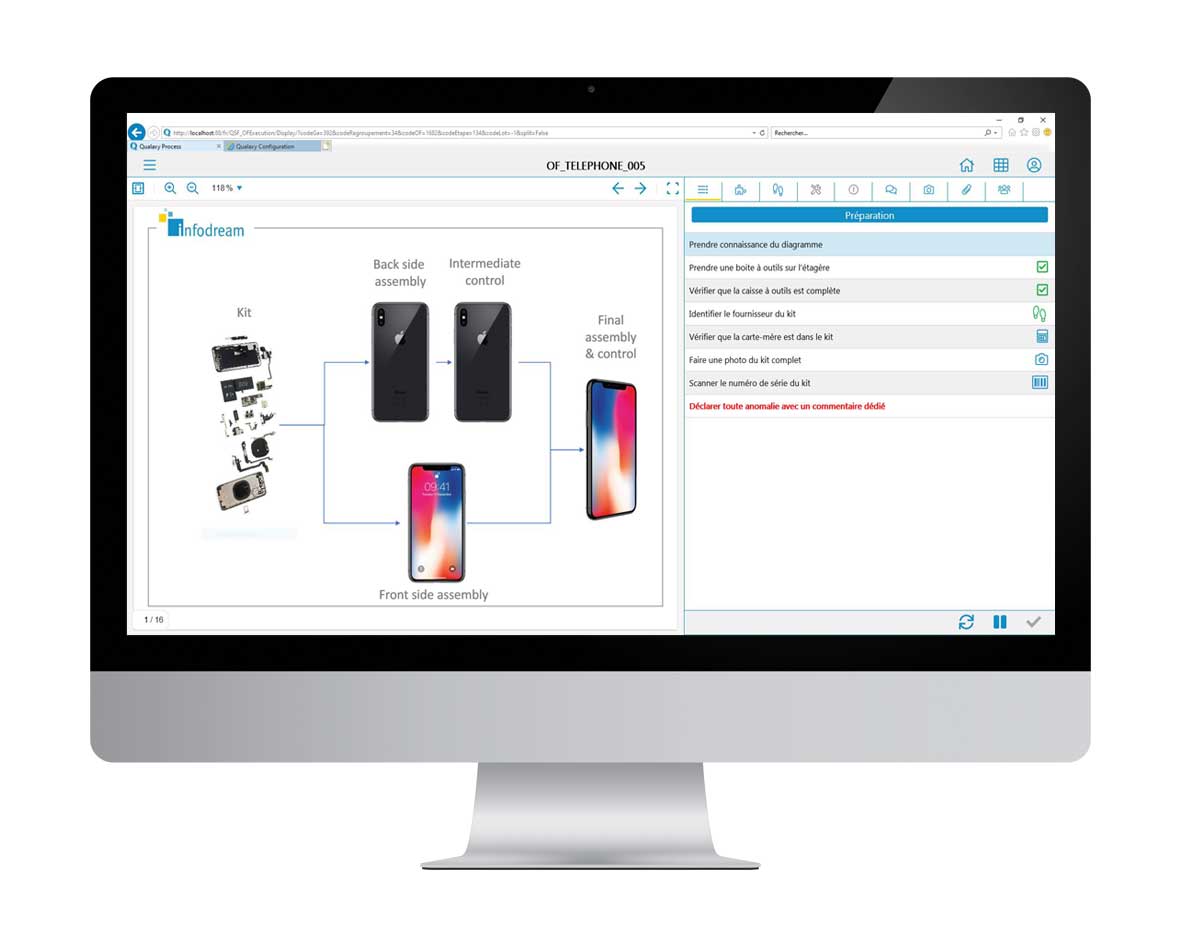

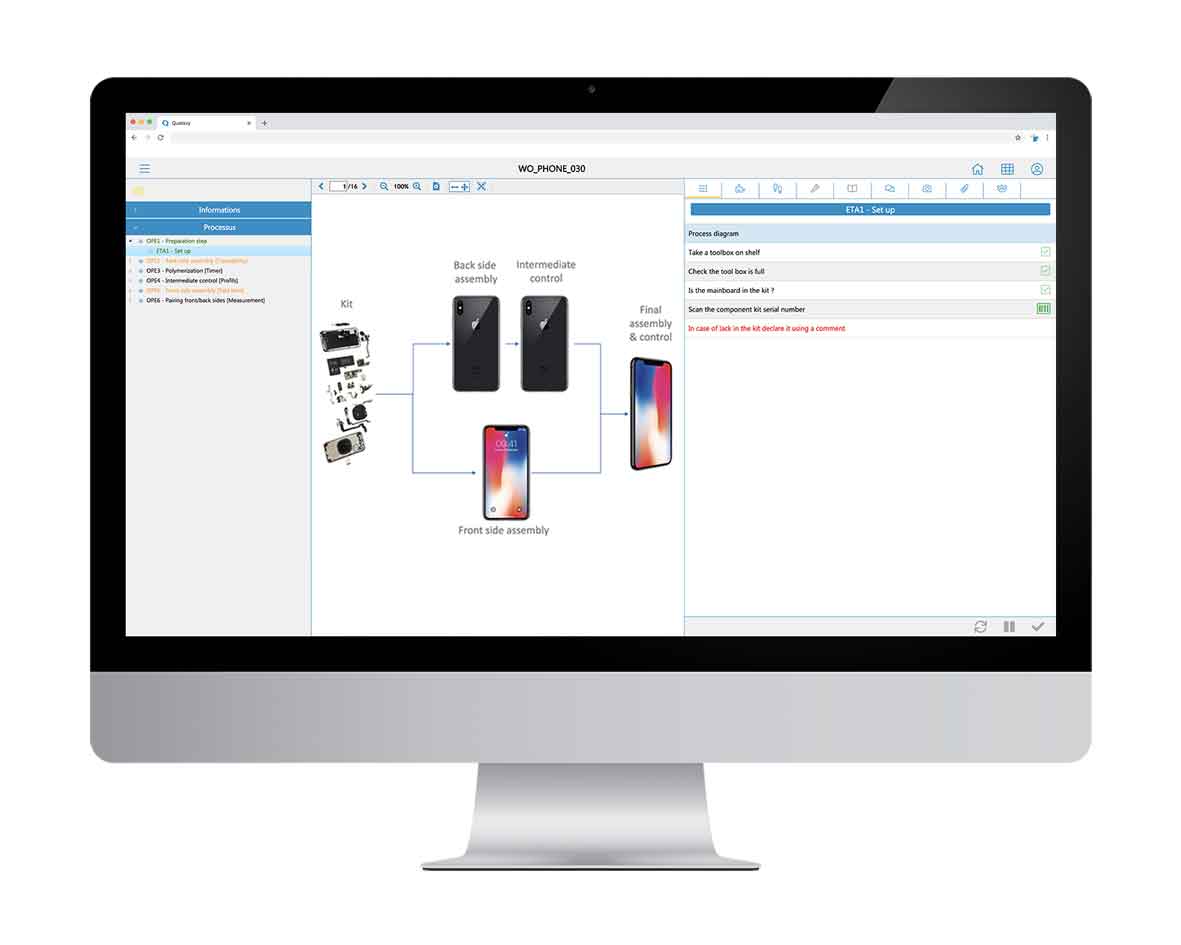

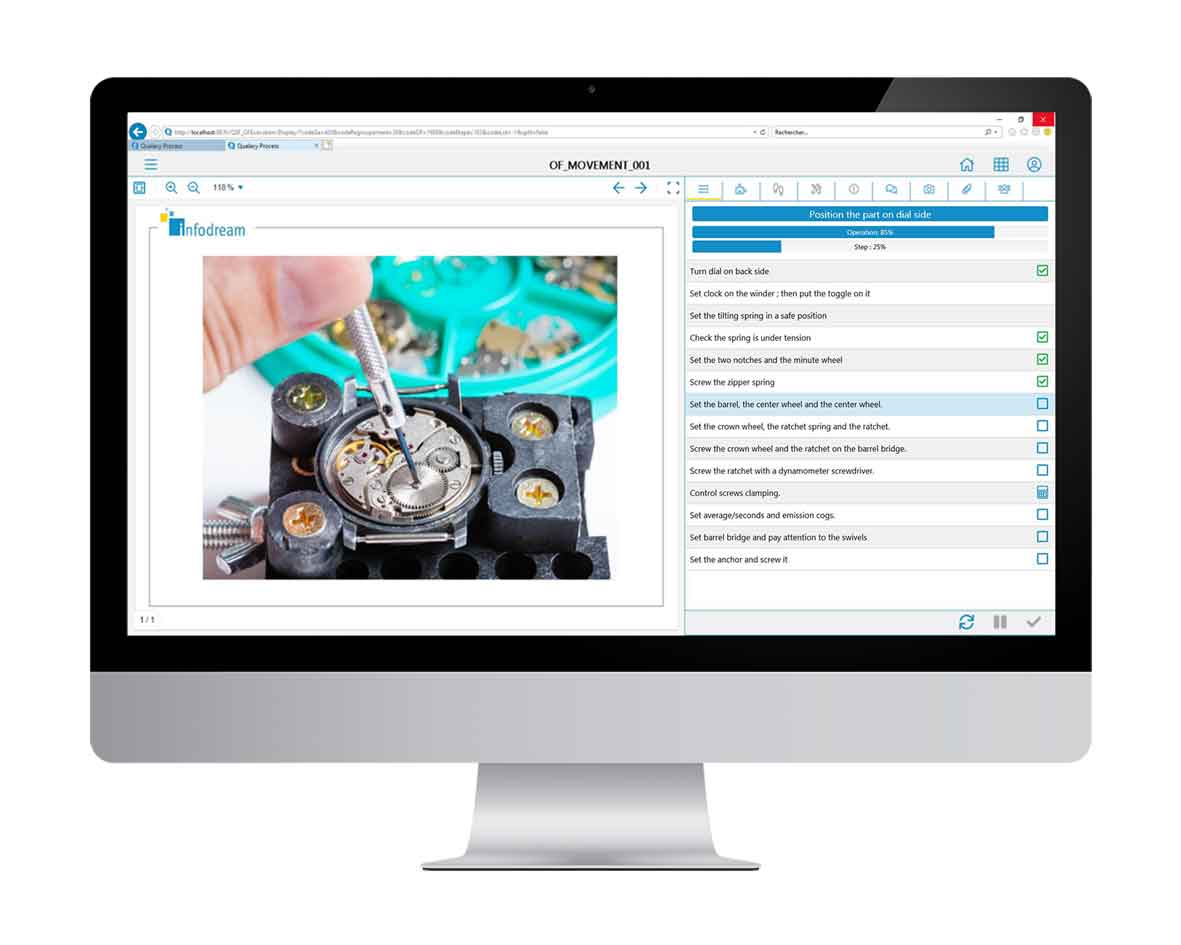

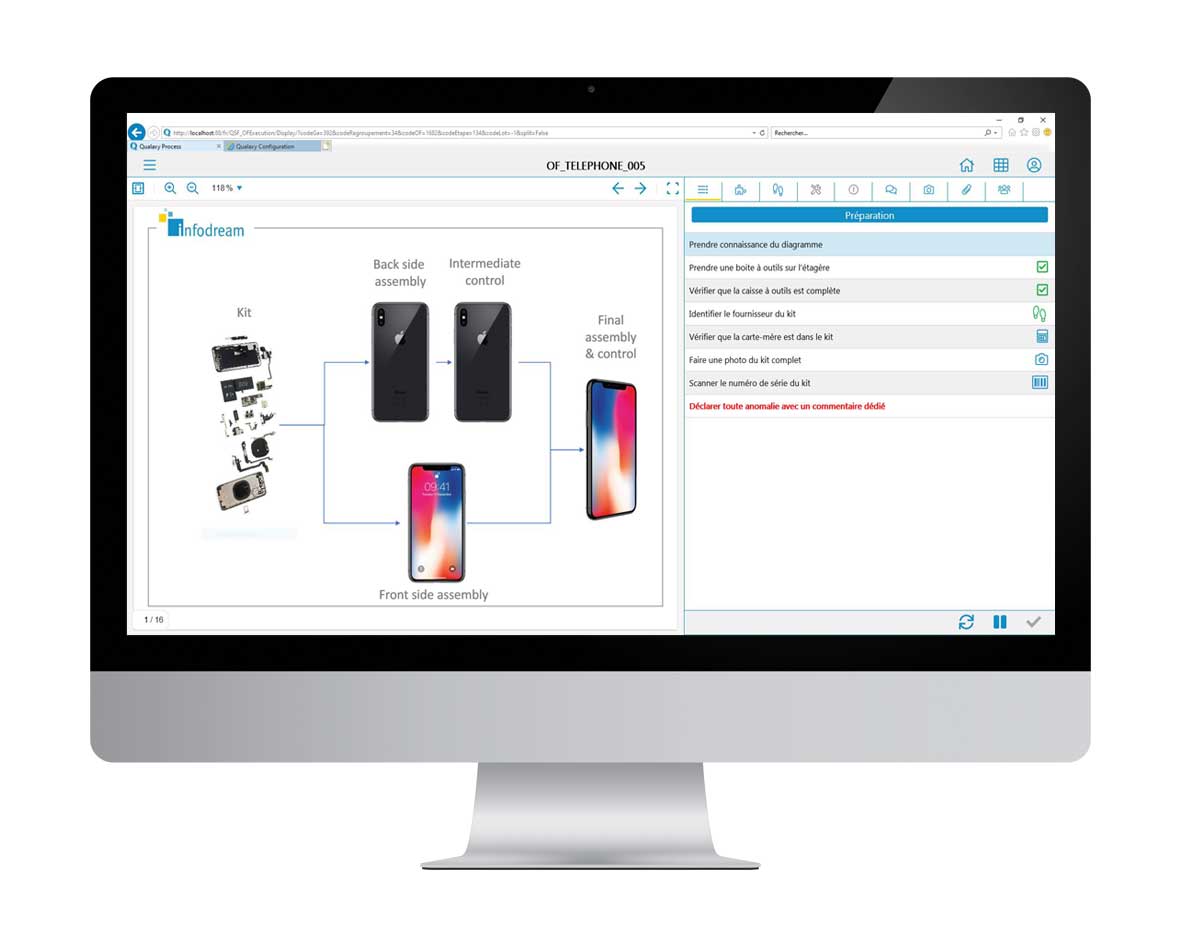

2. Electronic work instructions

Qual@xy Process offers step-by-step process support. Operators are clearly guided through all manufacturing operations.

Your current instruction documents can be used, without any changes, enabling a very fast commissioning.

Your processes can be structured with an extremely fine level of detail, always with a view to guiding the operator in compliance with what has been defined.

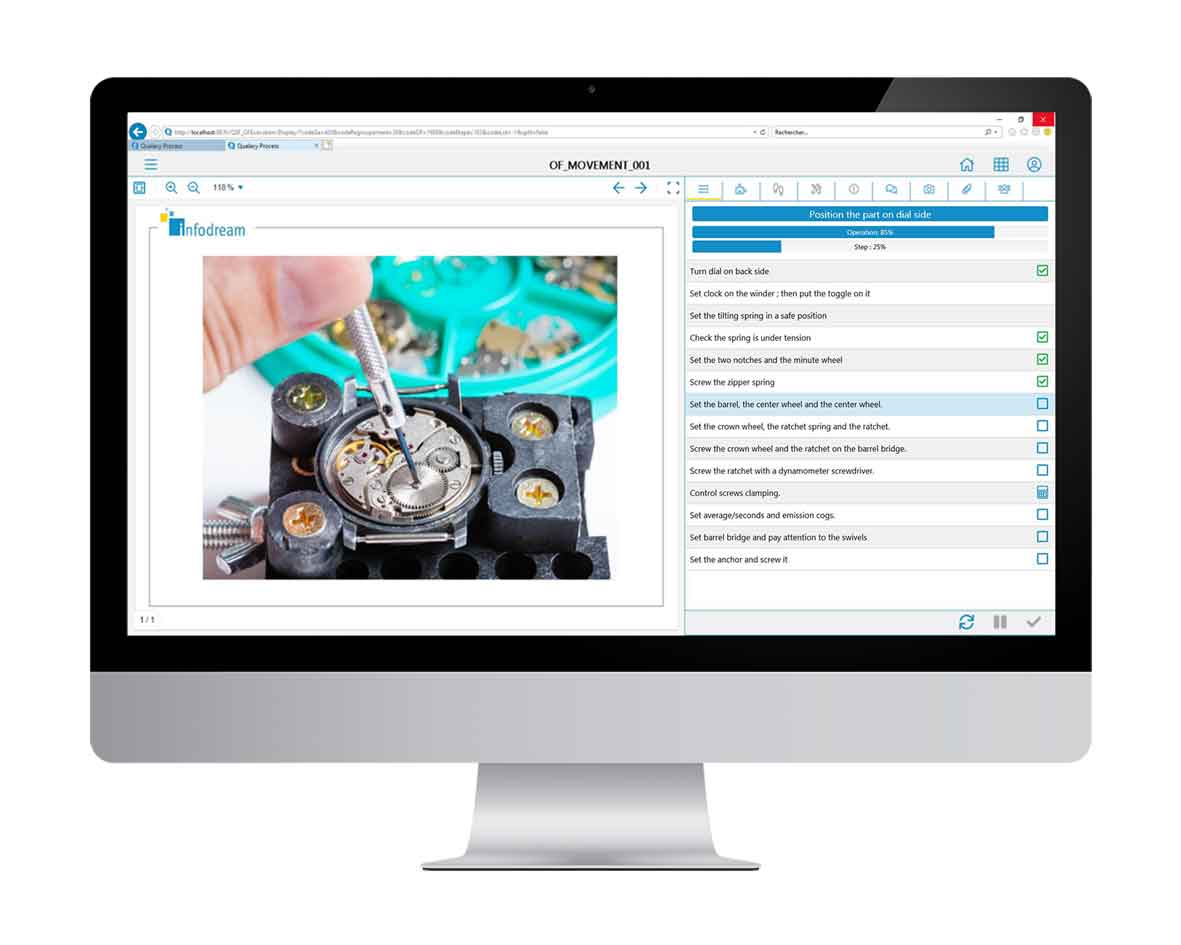

3. Recording of all production data

No more paper-based « checks »: they are replaced by electronic checks, measurements, traceability data, etc. All information is validated and time-stamped at each stage.

A « check » can be a simple validation, a request for confirmation, the entry of measurements or traceability information: material batches, component batches, serial numbers… a crucial function for industries that have to comply with NADCAP standards or, more generally, keep exhaustive traces of what has actually been carried out.

The database used is common for all the modules of the Suite: no redundancy or duplication of data.

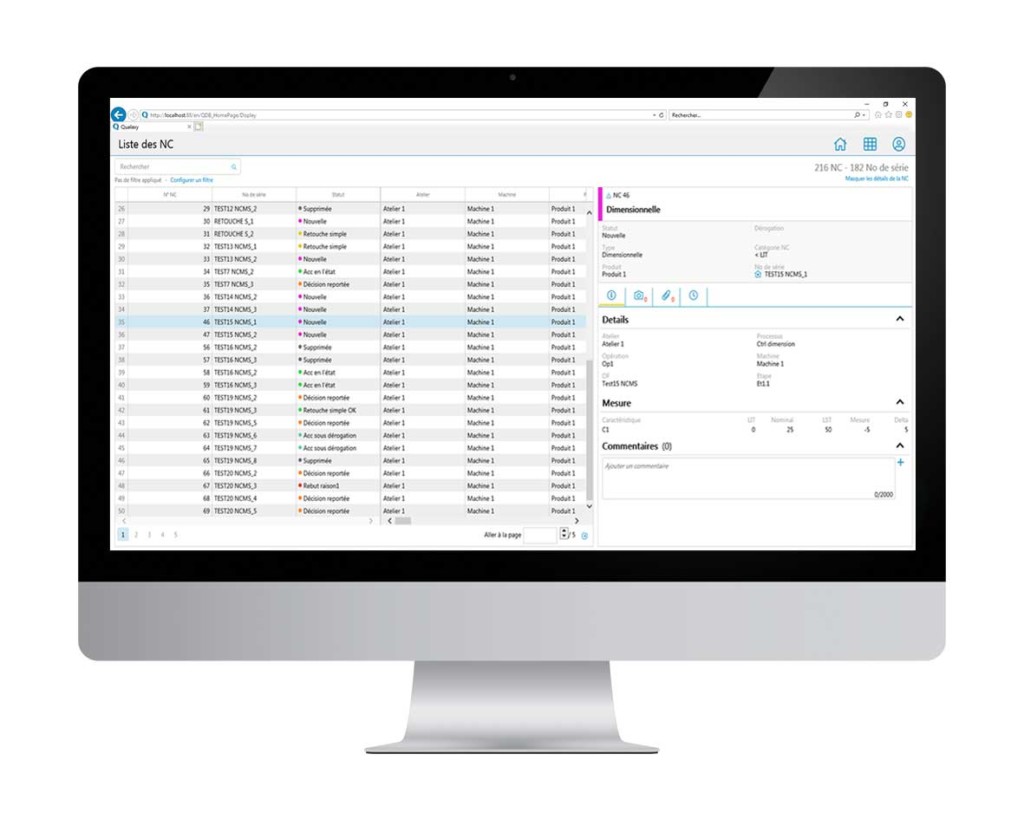

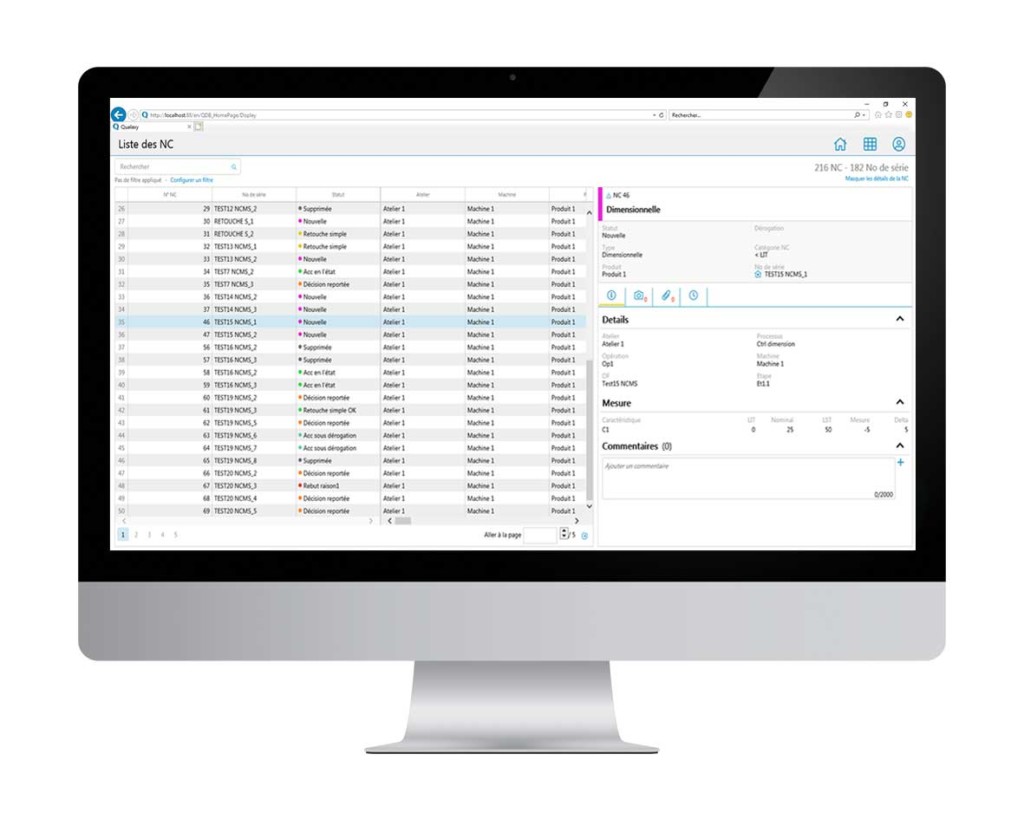

4. Non conformance management (NCMS)

Following the detection of a non-conformity (dimensional or aspect), this function is used when one or more parts need to undergo rework operations outside the normal flow. These rework operations can be standard and independent of the product reference. They can be easily selected from operation libraries that allow them to be grouped by theme.

You can also use the EasyRework function to repeat certain steps already carried out in the WO (works order).

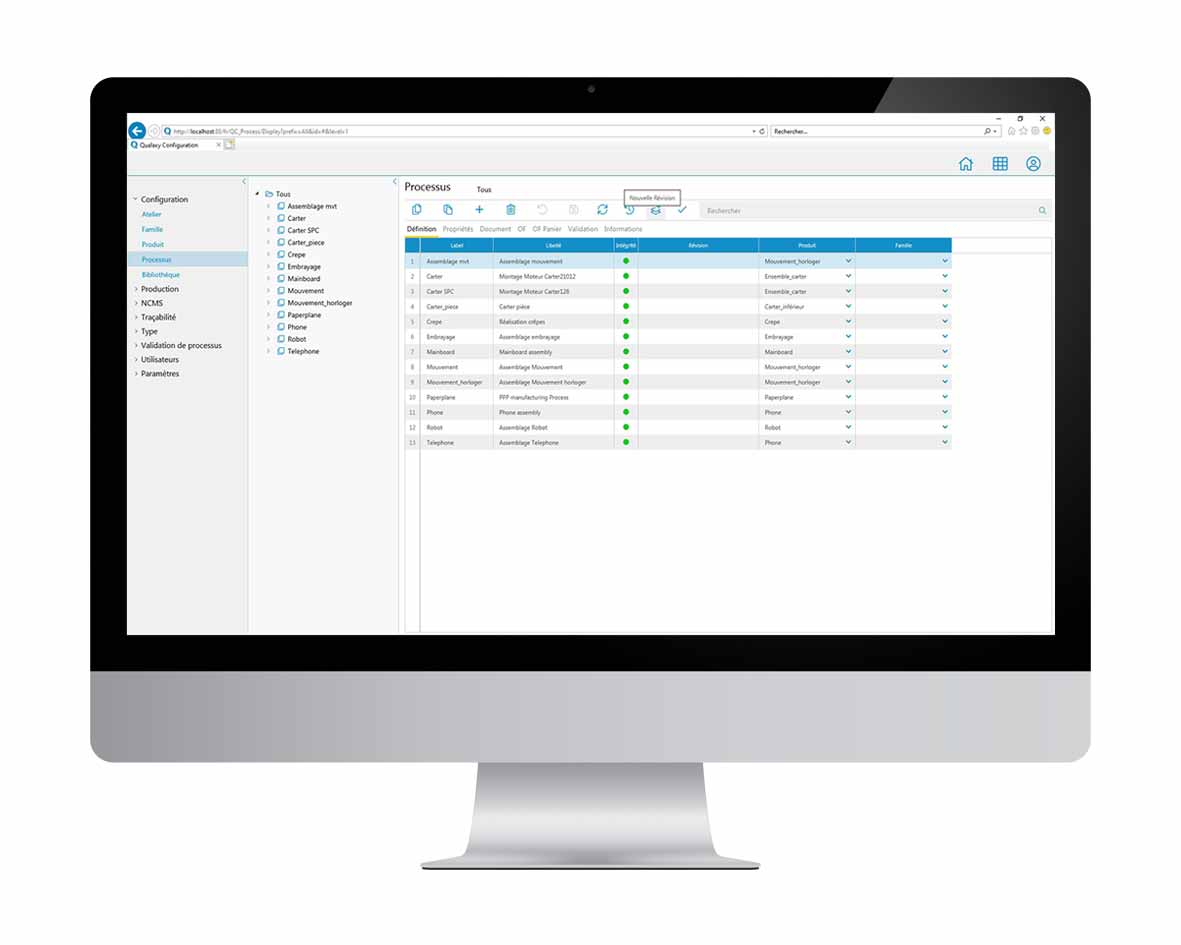

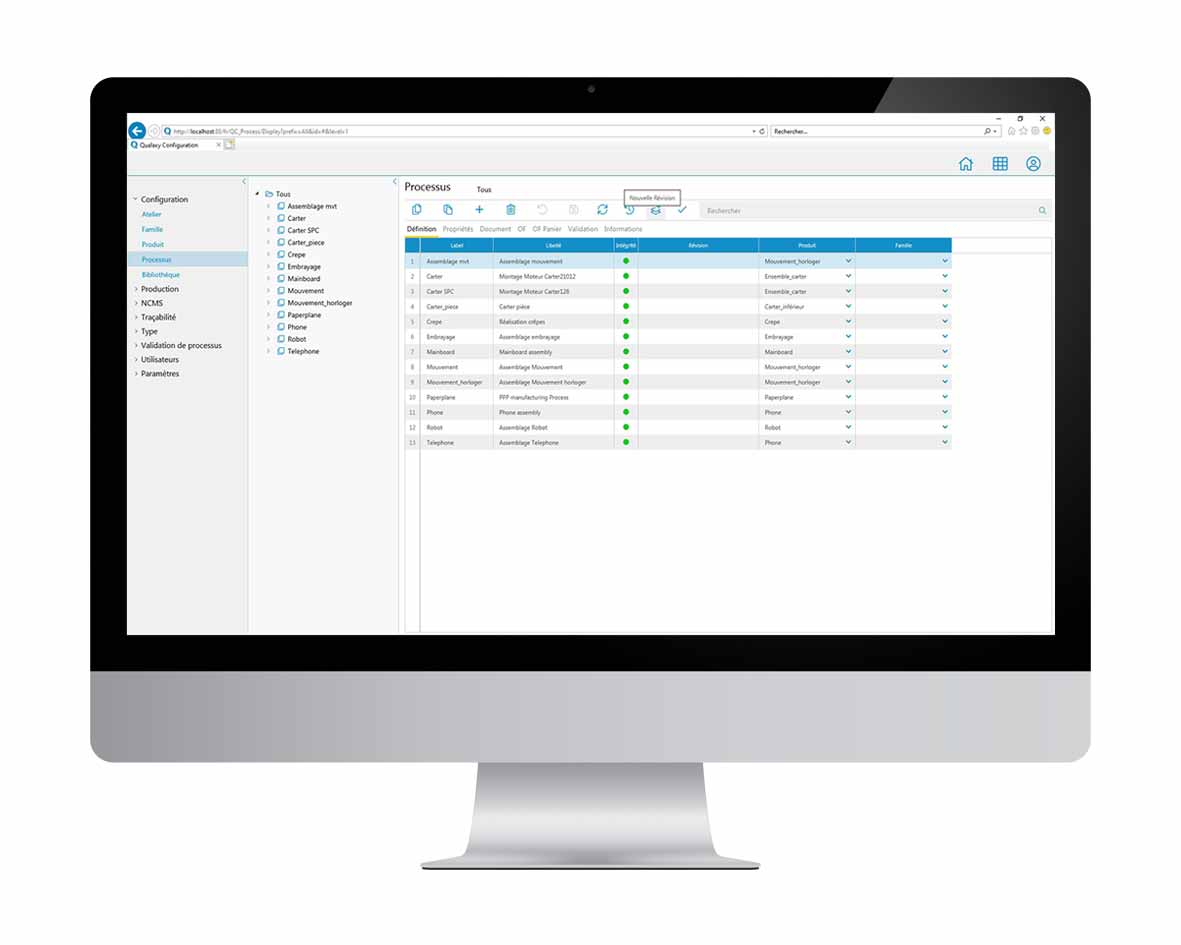

5. Routing validation workflow

Create and modify your processes in a test environment detached from production: the « sandbox ».

Each modification of your process is subject to validation by different users, with an established order, before it goes into production.

Depending on the group to which he belongs, the user will be able to write the ranges, or validate them.

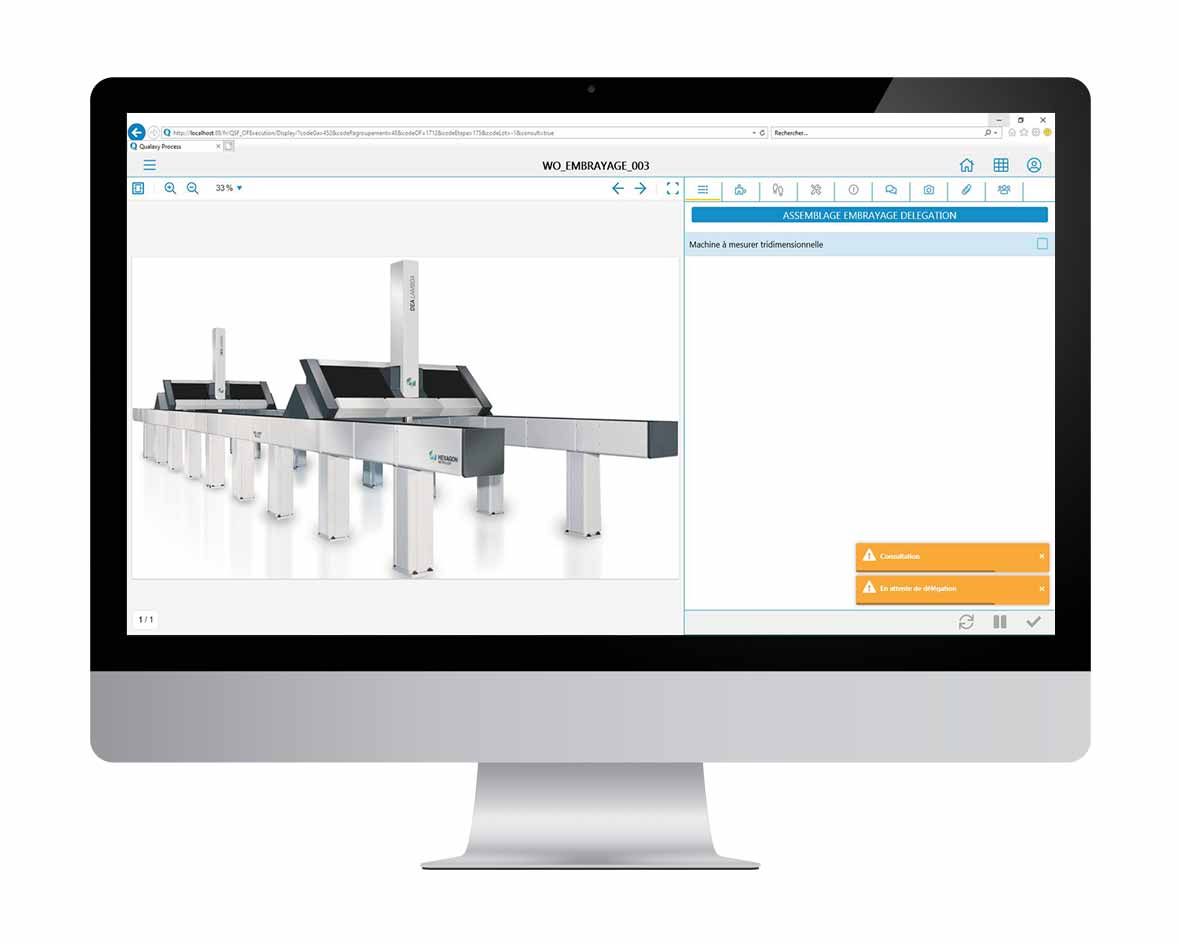

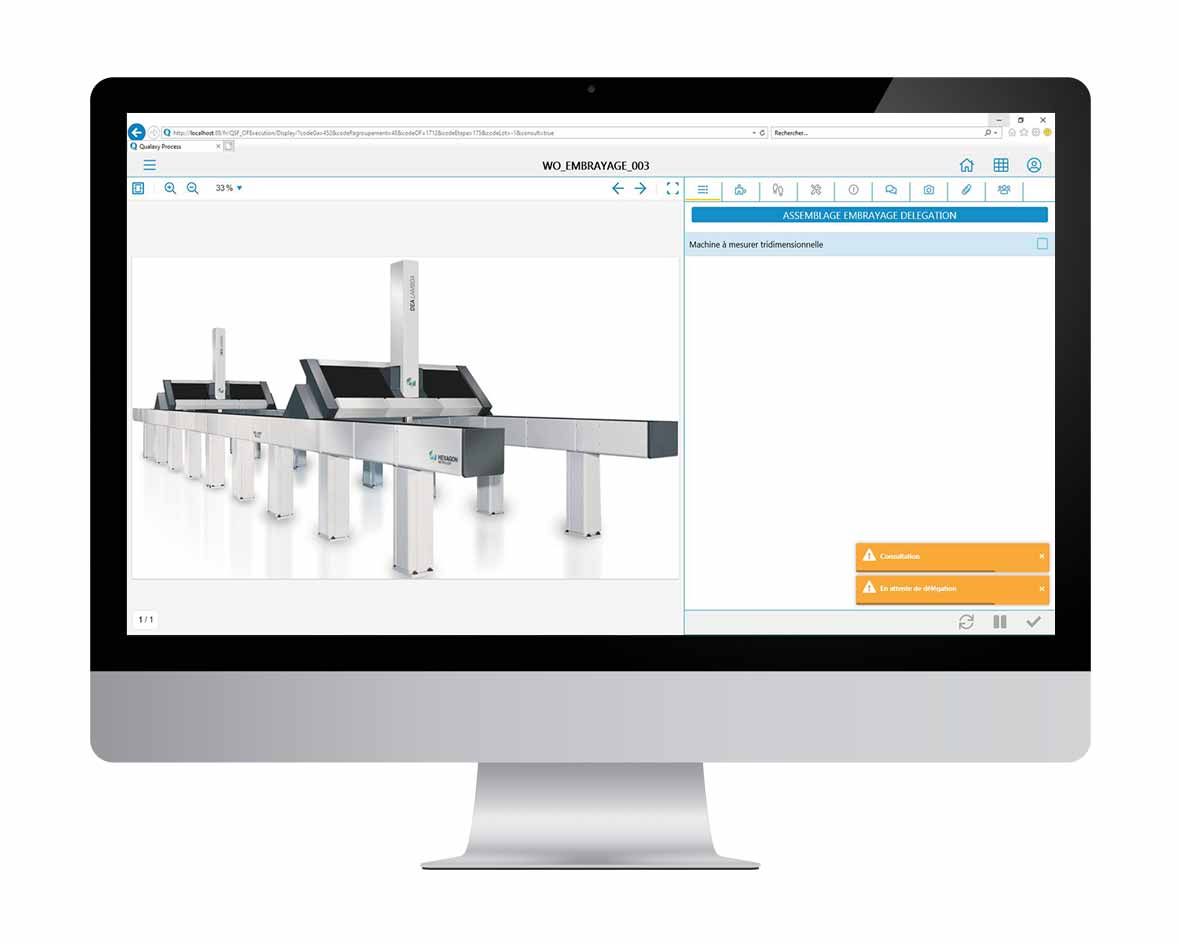

6. Subcontract an operation with the delegation function

During the process, the delegation function allows outsourcing of an operation, a step or a check to a third party application (a machine, a process, a subcontractor). The batch is temporarily taken out of the workflow and then returned once the work has been completed. You thus maintain the continuity and visibility of the manufacturing order and capitalise on the data or results!

7. Analyse the « Lean » performance of your production

Like all our tools, Qual@xy Process guides and reinforces your continuous improvement efforts.

Key quality and performance indicators are presented in dashboards to monitor the progress of efficiency, including « value-added time », « standard time analysis », identification of bottlenecks and analysis of the causes of downtime.

8. Easy IT deployment

Qual@xy Process is a full web application. It is very easy to deploy and manage by your IT department. It can be integrated with other applications, including SAP or other ERPs.

- Microsoft .NET technology

- Microsoft IIS web server

- Compatible with standard browsers: IE 11, Mozilla Firefox > 28, Opera > 47, Safari > 11, Chrome > 21.

See the case studies

See the video of a Ventana operator using Qualaxy Process

Paperless workshop

And therefore zero constraints! Your operators are finally guided by interactive work instructions.

"Where is this Work order ?"

Instant response from the shop floor, progress synchronised in real time with your ERP. A real time-saver!

Monitoring your production is good. In real time, it's better.

No more hunting for information. You know at all times where your production orders stand.

En savoir +

1. Management and traceability of WOs

No more need to go through the workshop to find out the status of a WO. With Qual@xy Process, you benefit from remote monitoring of the process : progress of your WO’s, their current status, the estimated time remaining and any unforeseen deviations.

If the WO is interrupted, a cause of interruption must be entered by the operator, allowing analysis of the causes and duration of the interruption.

All data is centralised, consolidated, shared and available in real time.

2. Electronic work instructions

Qual@xy Process offers step-by-step process support. Operators are clearly guided through all manufacturing operations.

Your current instruction documents can be used, without any changes, enabling a very fast commissioning.

Your processes can be structured with an extremely fine level of detail, always with a view to guiding the operator in compliance with what has been defined.

3. Recording of all production data

No more paper-based « checks »: they are replaced by electronic checks, measurements, traceability data, etc. All information is validated and time-stamped at each stage.

A « check » can be a simple validation, a request for confirmation, the entry of measurements or traceability information: material batches, component batches, serial numbers… a crucial function for industries that have to comply with NADCAP standards or, more generally, keep exhaustive traces of what has actually been carried out.

The database used is common for all the modules of the Suite: no redundancy or duplication of data.

4. Non conformance management (NCMS)

Following the detection of a non-conformity (dimensional or aspect), this function is used when one or more parts need to undergo rework operations outside the normal flow. These rework operations can be standard and independent of the product reference. They can be easily selected from operation libraries that allow them to be grouped by theme.

You can also use the EasyRework function to repeat certain steps already carried out in the WO (works order).

5. Routing validation workflow

Create and modify your processes in a test environment detached from production: the « sandbox ».

Each modification of your process is subject to validation by different users, with an established order, before it goes into production.

Depending on the group to which he belongs, the user will be able to write the ranges, or validate them.

6. Subcontract an operation with the delegation function

During the process, the delegation function allows outsourcing of an operation, a step or a check to a third party application (a machine, a process, a subcontractor). The batch is temporarily taken out of the workflow and then returned once the work has been completed. You thus maintain the continuity and visibility of the manufacturing order and capitalise on the data or results!

7. Analyse the « Lean » performance of your production

Like all our tools, Qual@xy Process guides and reinforces your continuous improvement efforts.

Key quality and performance indicators are presented in dashboards to monitor the progress of efficiency, including « value-added time », « standard time analysis », identification of bottlenecks and analysis of the causes of downtime.

8. Easy IT deployment

Qual@xy Process is a full web application. It is very easy to deploy and manage by your IT department. It can be integrated with other applications, including SAP or other ERPs.

- Microsoft .NET technology

- Microsoft IIS web server

- Compatible with standard browsers: IE 11, Mozilla Firefox > 28, Opera > 47, Safari > 11, Chrome > 21.

See the case studies

See the video of a Ventana operator using Qual@xy Process

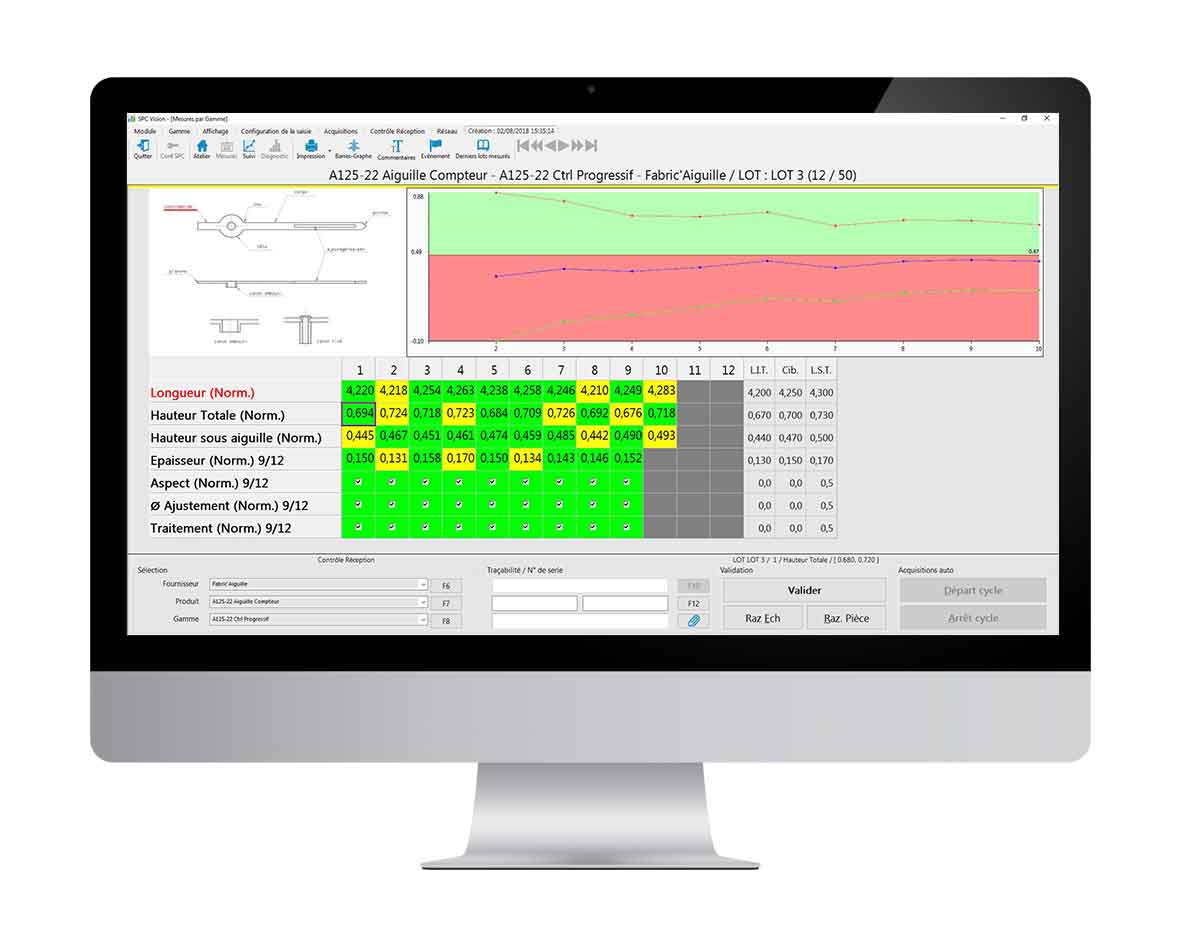

Anticipating Quality

With SPC monitoring, detect in real time the progressive drifts of your productions before the appearance of non-conformities.

Take advantage of our expertise in SPC

And take advantage of our powerful and universal tool for large or small series.

"Where are my faults?"

Forget this question: identify then eradicate the root causes.

Learn more

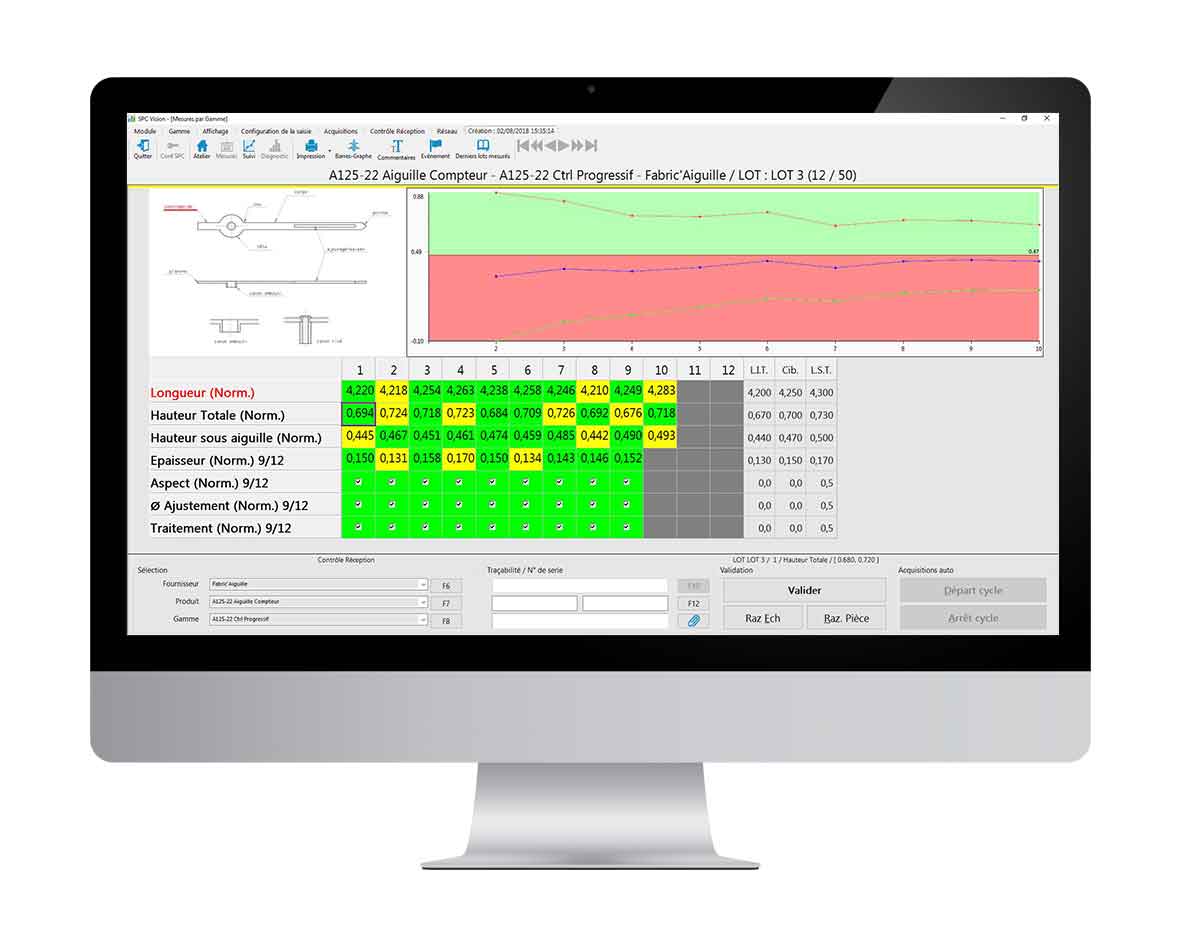

Real-time network operation

All data is recorded, analysed and displayed (or edited) in real time, which is essential for good decision-making.

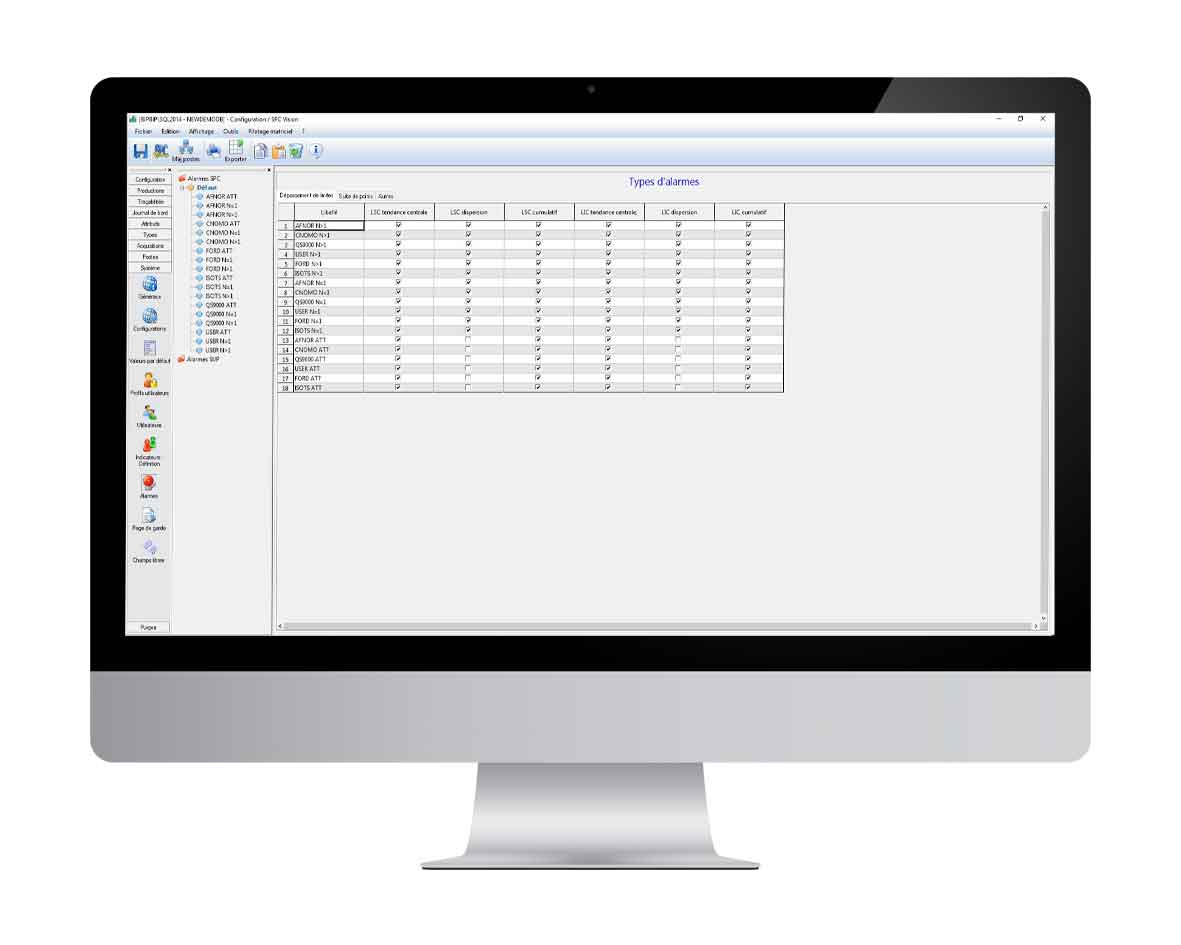

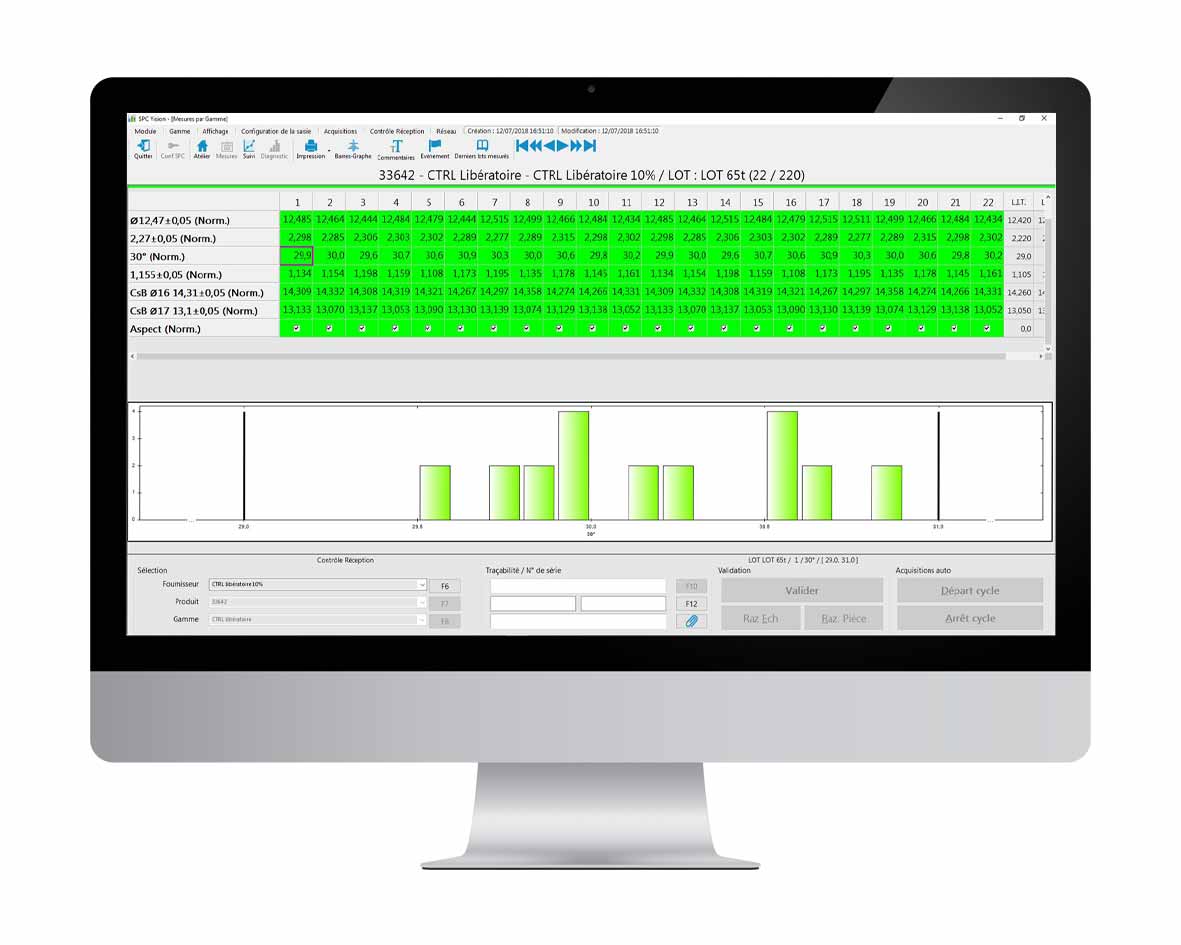

SPC & Statistical Analysis

The Qual@xy SPC module has been designed as a quality supervisor. A synoptic of the workshop presents in real time all the current statistical alarms. This way, the user can concentrate only on incidents, without wasting time.

Robust and comfortable operator interface

A major asset of Qual@xy SPC is its workshop ergonomics. Operators immediately adopt it for its speed of implementation, comfort and simplicity.

Measurement management for the company

Qual@xy SPC is a real-time network system that operates a central database.

Standards compliance and traceability

Compliance with standards and traceability management are extremely important for the majority of our customers: this is one of Qual@xy SPC’s strong points. We work intensively with sectors such as aerospace and pharmaceuticals where standards and regulations are very strict.

Advanced analysis tools

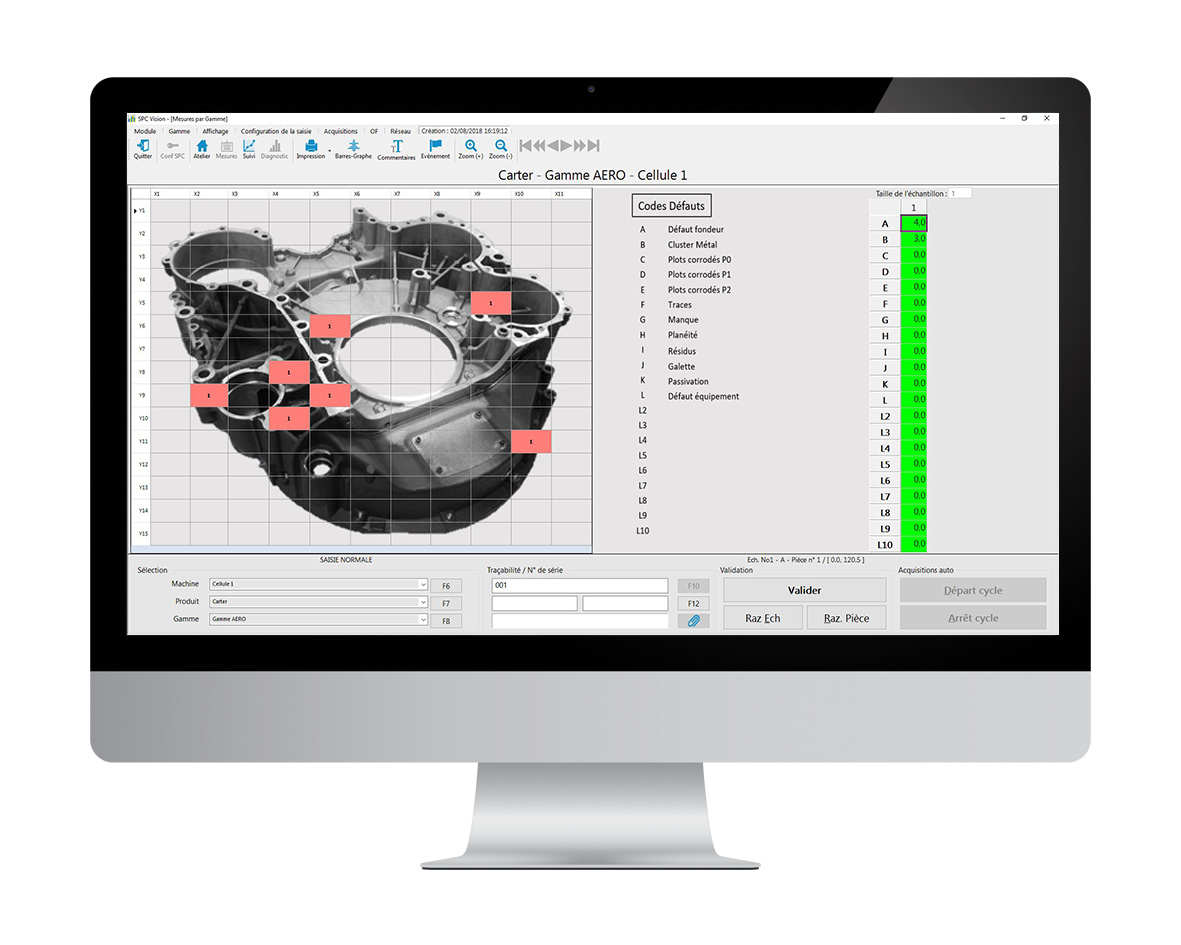

Defect Map

Defect Map allows you to associate the location and dimensional characteristics of the defects you detect with their location. It is a very powerful tool for analysing all aspects of non-destructive testing in the form of a map: visual, radiology, penetrant testing, ultrasound, etc…

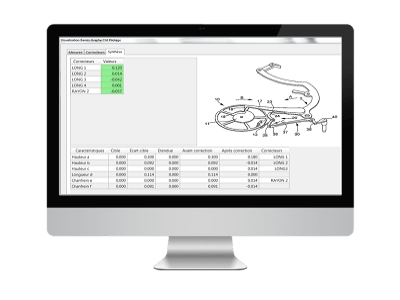

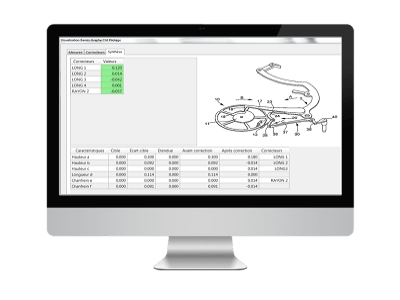

Matrix control

A control matrix models the links between the machine parameters and the dimensions of the part being manufactured. When the measurements are validated, the SPC control function automatically calculates the best corrections to be made according to the deviations from the target observed on the measured parts.

R&R / MSA: calculation of inspection process capability

The R&R module of the SPC function allows the calculation of all repeatability and reproducibility indicators required by MSA and other standards, as well as the graphical representation of variation sources. An R&R study should be a prerequisite for SPC analysis.

Anticipating Quality

With SPC monitoring, detect in real time the progressive drifts of your productions before the appearance of non-conformities.

Take advantage of our expertise in SPC

And take advantage of our powerful and universal tool for large or small series.

"Where are my faults?"

Forget this question: identify then eradicate the root causes.

Learn more

Real-time network operation

All data is recorded, analysed and displayed (or edited) in real time, which is essential for good decision-making.

SPC & Statistical Analysis

The Qual@xy SPC module has been designed as a quality supervisor. A synoptic of the workshop presents in real time all the current statistical alarms. This way, the user can concentrate only on incidents, without wasting time.

Robust and comfortable operator interface

A major asset of Qual@xy SPC is its workshop ergonomics. Operators immediately adopt it for its speed of implementation, comfort and simplicity.

Measurement management for the company

Qual@xy SPC is a real-time network system that operates a central database.

Standards compliance and traceability

Compliance with standards and traceability management are extremely important for the majority of our customers: this is one of Qual@xy SPC’s strong points. We work intensively with sectors such as aerospace and pharmaceuticals where standards and regulations are very strict.

Advanced analysis tools

Defect Map

Defect Map allows you to associate the location and dimensional characteristics of the defects you detect with their location. It is a very powerful tool for analysing all aspects of non-destructive testing in the form of a map: visual, radiology, penetrant testing, ultrasound, etc…

Matrix control

A control matrix models the links between the machine parameters and the dimensions of the part being manufactured. When the measurements are validated, the SPC control function automatically calculates the best corrections to be made according to the deviations from the target observed on the measured parts.

R&R / MSA: calculation of inspection process capability

The R&R module of the SPC function allows the calculation of all repeatability and reproducibility indicators required by MSA and other standards, as well as the graphical representation of variation sources. An R&R study should be a prerequisite for SPC analysis.

Masked costs: looking for lost time

With the traceability of time spent, you know the true cost of your production and your bottlenecks.

360° control

In one click, visualise your KPIs and the performance of your workshop.

Datamining

Fast, efficient and personalised analyses according to your criteria.

Learn more

1/ Analyse the performance of your workshop

A synthetic and pictorial display of your most relevant quality and productivity KPIs is built automatically.

2/ Managers, tool up your management activity

By presenting an immediate diagnosis of your production performance, this tool proposes areas for continuous improvement to enable you to make the best decisions.

3/ Integrated datamining

Get fast, relevant and personalised analyses according to your own criteria.

Produce detailed reports for each production batch or serialised part.

4/ Automation and customisation

Qual@xy Dashboard provides you with a dashboard of indicators describing the workshop overall performance. The home page is fully customisable according to the desired scope and indicators.

Masked costs: looking for lost time

With the traceability of time spent, you know the true cost of your production and your bottlenecks.

360° control

In one click, visualise your KPIs and the performance of your workshop.

Datamining

Fast, efficient and personalised analyses according to your criteria.

Learn more

1/ Analyse the performance of your workshop

A synthetic and pictorial display of your most relevant quality and productivity KPIs is built automatically.

2/ Managers, tool up your management activity

By presenting an immediate diagnosis of your production performance, this tool proposes areas for continuous improvement to enable you to make the best decisions.

3/ Integrated datamining

Get fast, relevant and personalised analyses according to your own criteria.

Produce detailed reports for each production batch or serialised part.

4/ Automation and customisation

Qual@xy Dashboard provides you with a dashboard of indicators describing the workshop overall performance. The home page is fully customisable according to the desired scope and indicators.

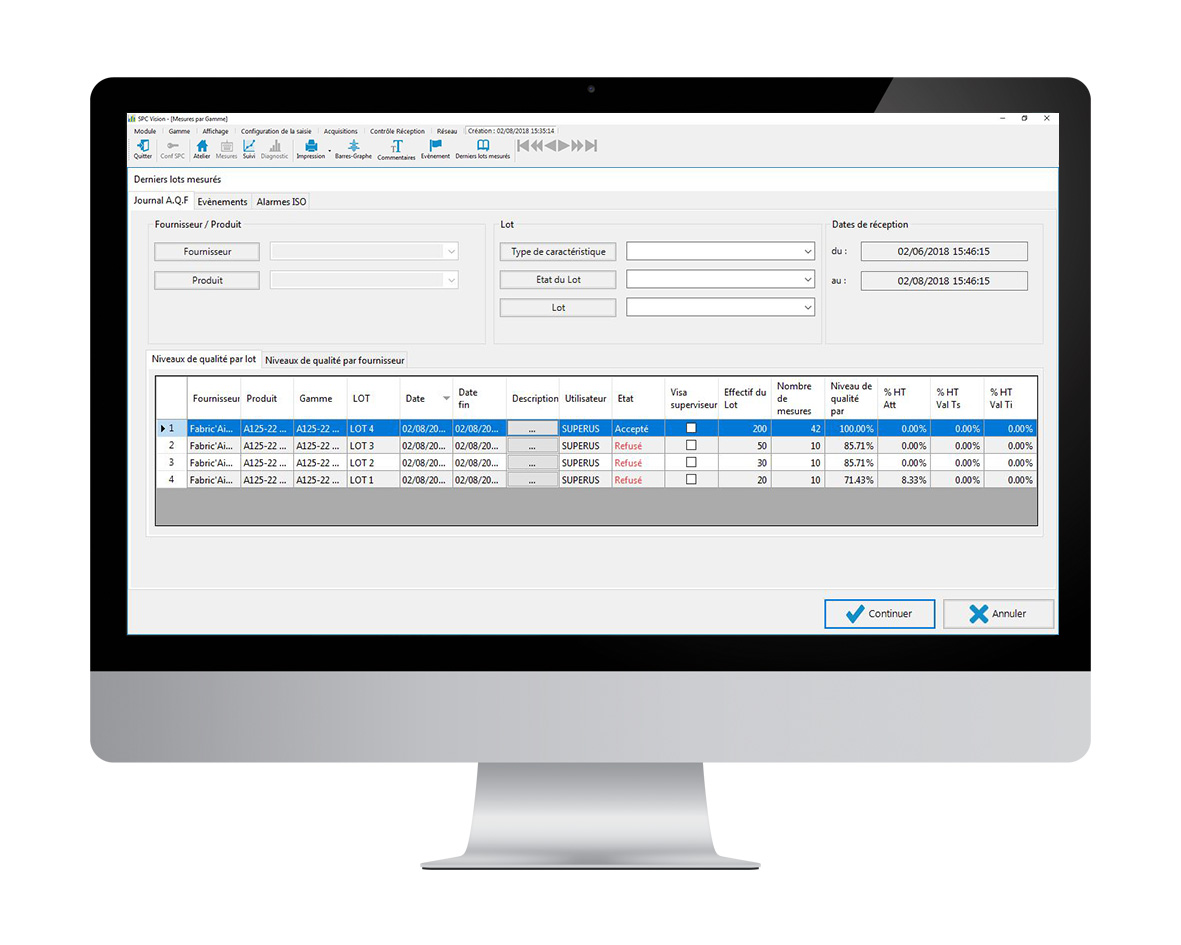

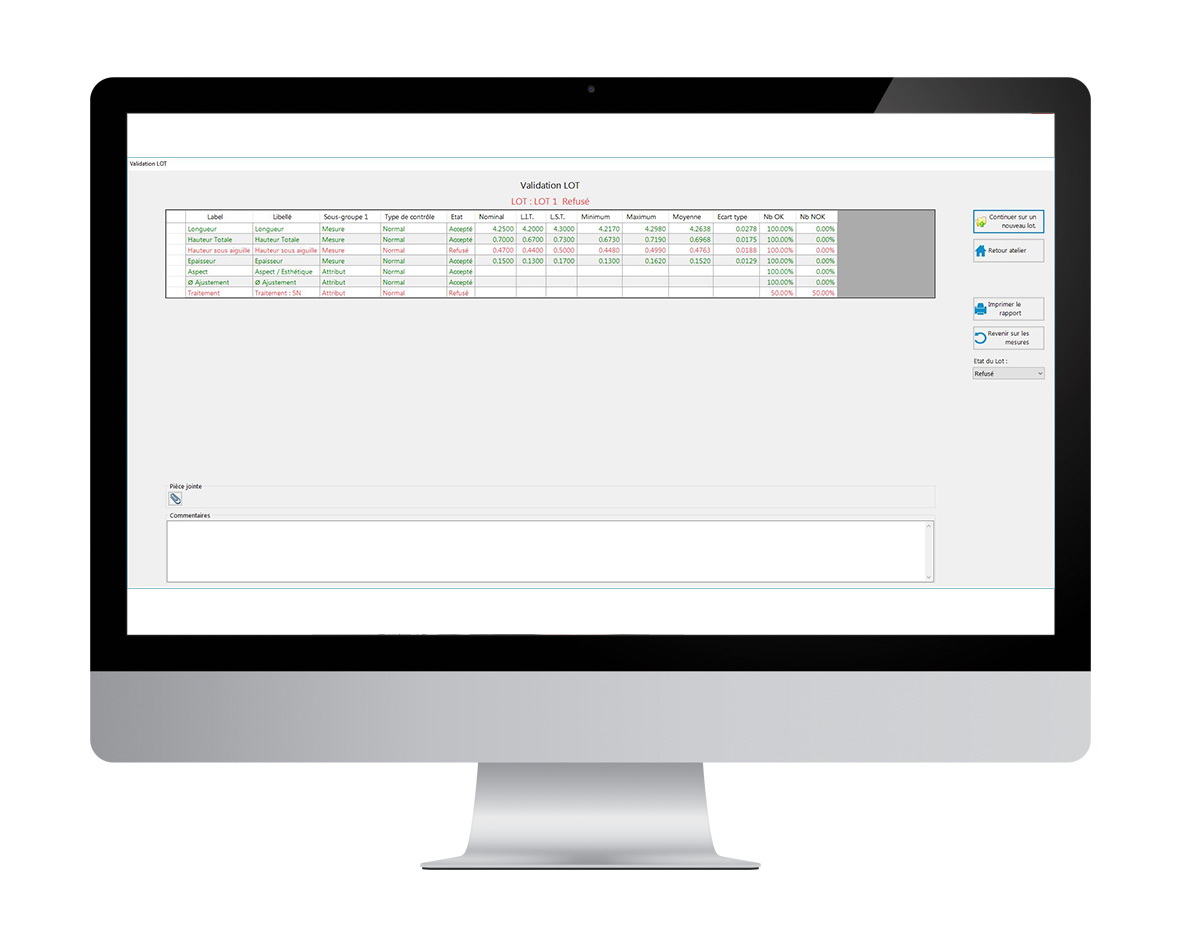

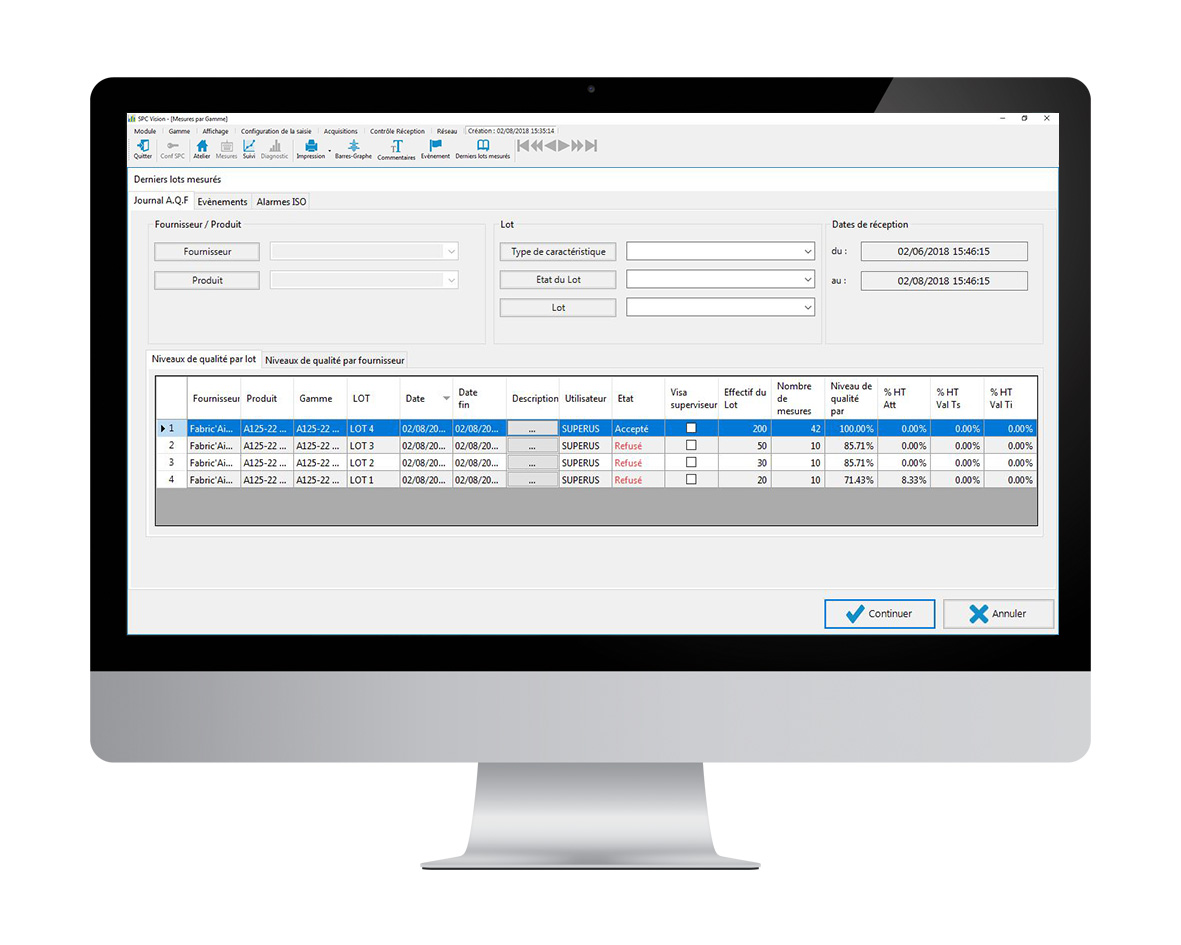

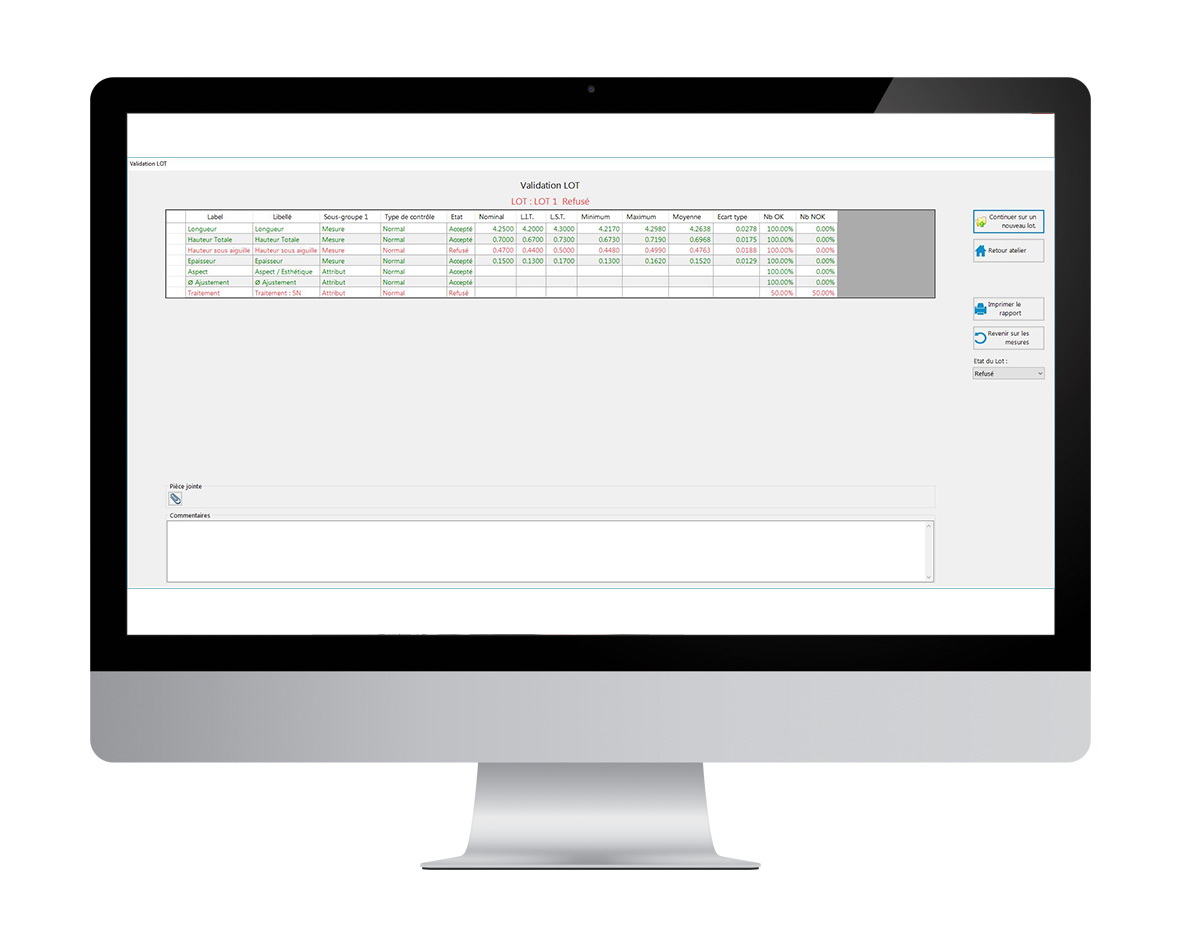

Supplier quality: the phantom threat

Your incoming controls are optimised: a real barrier against imported non-compliance!

Save time, of course.

Who can afford to waste time checking what is not necessary?

360° control

In one click, visualise your KPIs and the performance of your workshop.

Learn more

1/ Optimise the quality of your incoming batches

Efficiently organise a quality control activity at reception, according to official or in-house standards. Simply enter the batch size, your AQL and the level of control monitored: Qual@xy Control guides you to carry out the most efficient inspection, no more and no less.

2/ Dynamic characteristic control

Take into account the results of previous controls to lighten or strengthen inspection, characteristic by characteristic. Why spend time systematically checking a characteristic that is known to have a very high chance of compliance?

3/ Help in the decision to accept

Finally, the application provides you with statistical advice on whether to accept or reject a supplier batch. However, it remains at your discretion to make the final decision.

4/ Easily compare the quality level of your suppliers

Qual@xy Control compiles the results of the controls carried out to build a Supplier Quality Assurance log, allowing you to objectively compare the quality of the products received from your different suppliers.

Supplier quality: the phantom threat

Your incoming controls are optimised: a real barrier against imported non-compliance!

Save time, of course.

Who can afford to waste time checking what is not necessary?

360° control

In one click, visualise your KPIs and the performance of your workshop.

Learn more

1/ Optimise the quality of your incoming batches

Efficiently organise a quality control activity at reception, according to official or in-house standards. Simply enter the batch size, your AQL and the level of control monitored: Qual@xy Control guides you to carry out the most efficient inspection, no more and no less.

2/ Dynamic characteristic controle

Take into account the results of previous controls to lighten or strengthen inspection, characteristic by characteristic. Why spend time systematically checking a characteristic that is known to have a very high chance of compliance?

3/ Help in the decision to accept

Finally, the application provides you with statistical advice on whether to accept or reject a supplier batch. However, it remains at your discretion to make the final decision.

4/ Easily compare the quality level of your suppliers

Qual@xy Control compiles the results of the controls carried out to build a Supplier Quality Assurance log, allowing you to objectively compare the quality of the products received from your different suppliers.