The key functions of Qual@xy Process

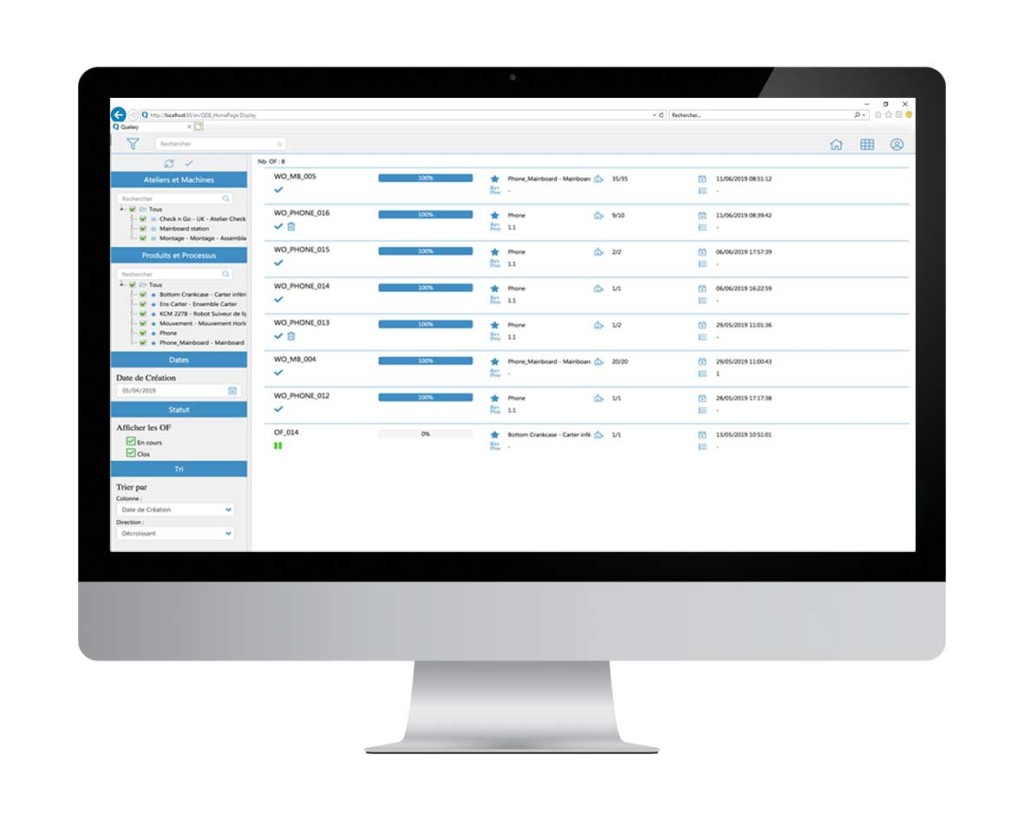

1. Work Order management

Walking the shop floor to see the status of a production order is not needed. Qualaxy Process (formerly named Check’n Go) allows you to remotely track progress, view current status, estimate completion and view unplanned deviations.

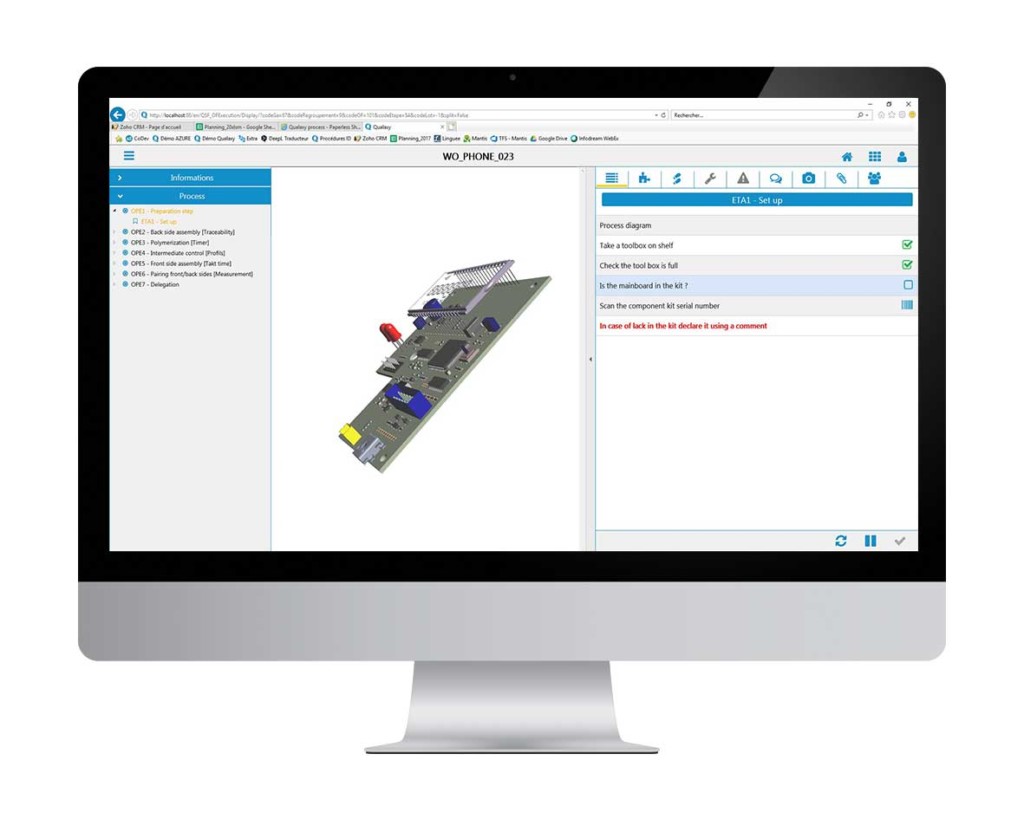

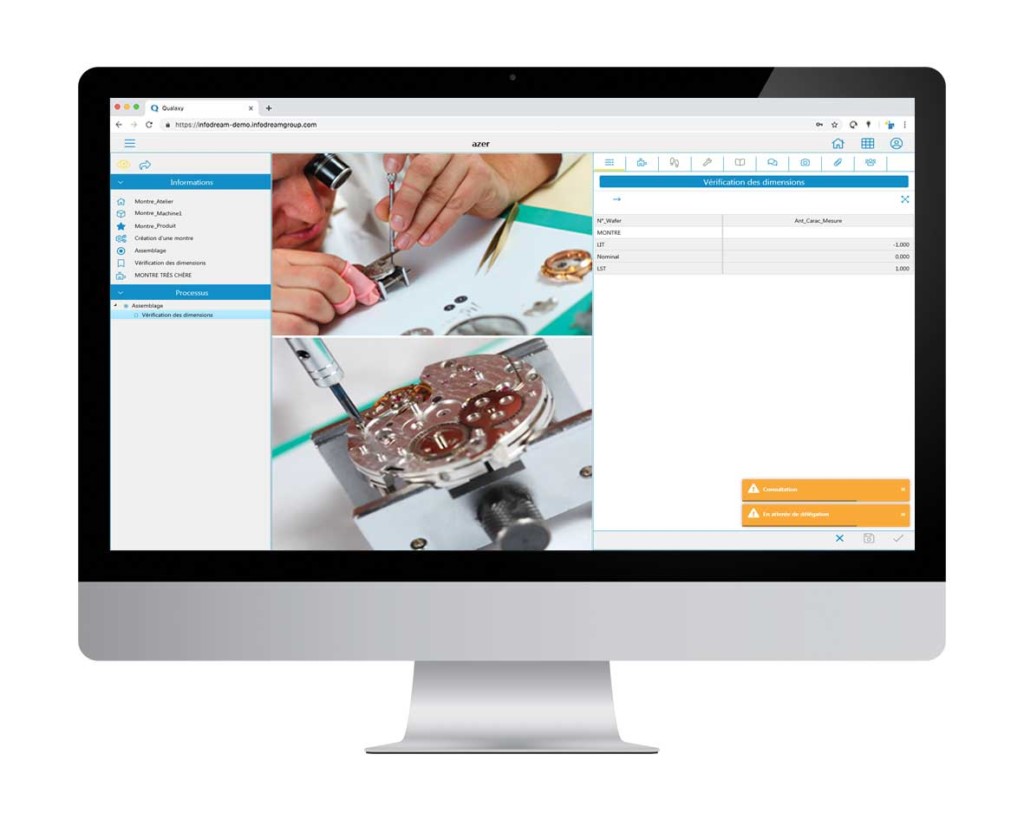

2. Electronic job card and operator work instructions

Provides a step by step plan clearly guiding operators through each activity. Your current instructions and procedures can be used but the structure of Qualaxy Process provides a greater level of detail for the operators. Working methods, drawings, tooling, equipment and health and safety precautions are all defined for each step.

3. Traceability and compliance

Paper check-sheets and travelers are eliminated with all process checks, measurements and traceability information electronically recorded at each step of the process. This could range from simply confirming a process setting, recording a material batch or importing complex measurement data. This aspect is crucial for companies subject to NADCAP requirements and Individual operator certification privileges are managed.

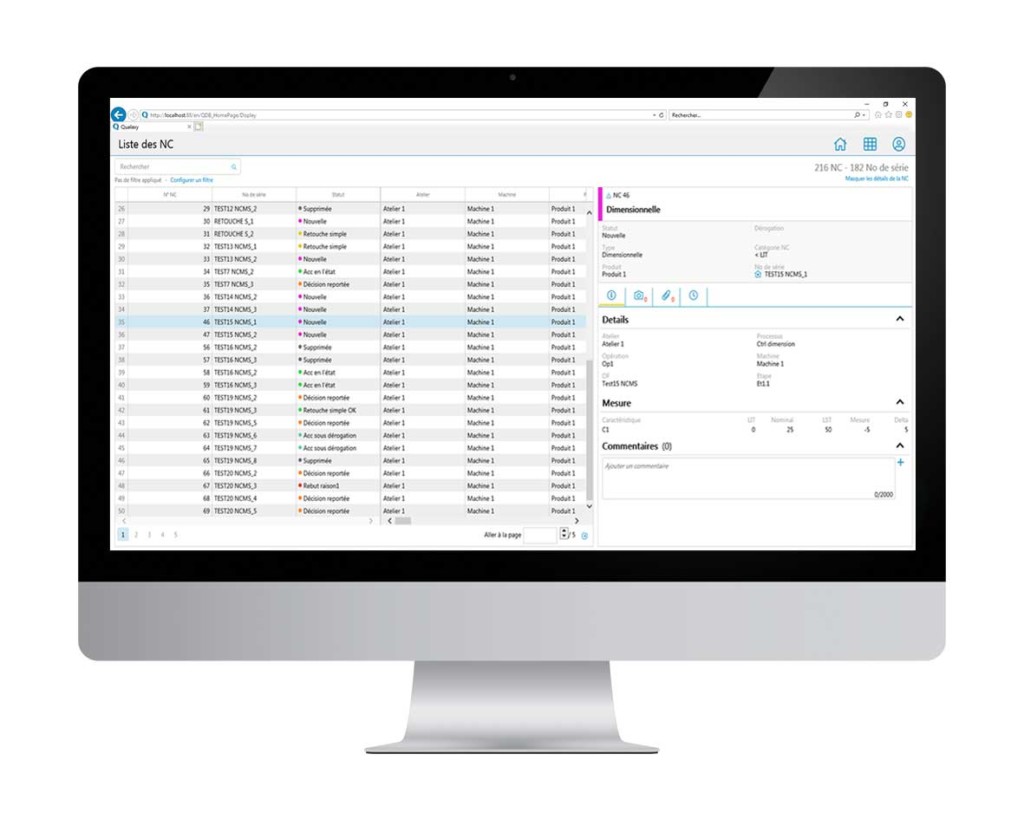

4. Non Conformance Management System (NCMS)

Qualaxy NCMS module allows you to detect, manage and correct non-conforming products.

The non-conformance can be detected automatically as part of a defined process check or created manually. The NC part is then managed through a structured, flexible workflow in order to define and implement the required action.

The NCMS provides integrated rework functions to ensure rectification can be implemented as efficiently as possible. This is achieved using ‘standard rework processes’ or by defining a new process using the ‘standard rework operations’ library.

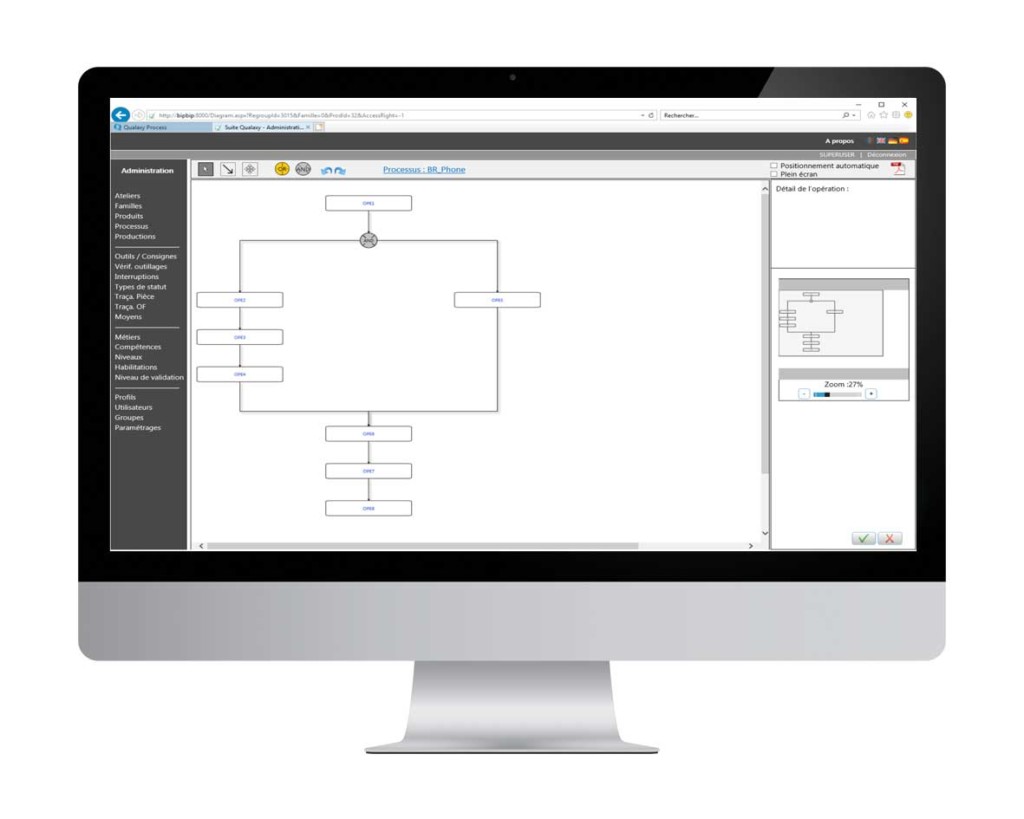

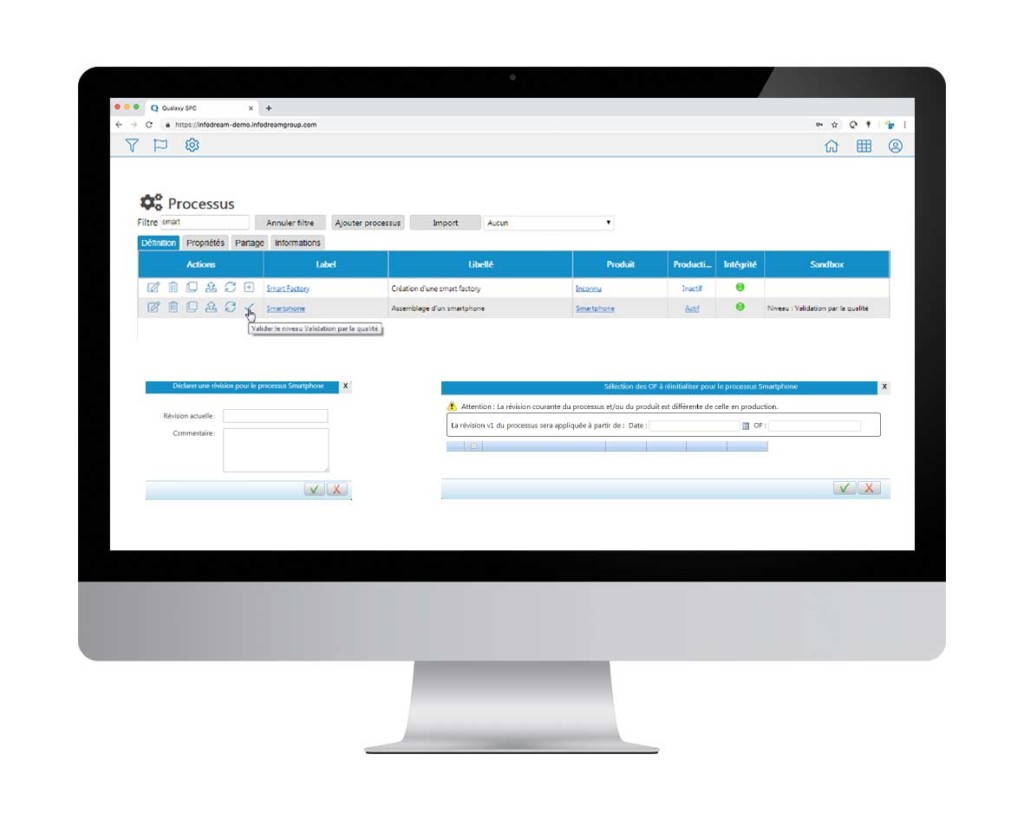

5. Production process approval

This feature ensures that new production processes (or modifications to existing process) cannot be released into production before they have been approved. There can be multiple levels of approval and until the specified approver has accepted the process, it cannot be used in production.

6. ‘Sub-contract’ an operation to another machine

During the process, the delegation function makes it possible to subcontract an operation, step or check to another machine via a third-party application. The batch is temporarily leaves the workflow, then returns once the work is complete thus preserving the continuity of the production order and capitalizing the data & results from the delegated machine.

7. Analyze production performance

As with all our software, Qualaxy Process drives and supports your continuous improvement efforts. Key quality and performance measures such as standard time performance, value adding time and analysis of process stoppages and bottlenecks help increase productivity and efficiency.

8. Simple IT integration and deployment

Qualaxy Process is a full web application, enabling easy deployment and management which can be integrated with other business IT systems including SAP and other ERP.

- Microsoft .NET Technology

- Microsoft IIS Web Server

- Compatible with standard browsers: IE 11, Mozilla Firefox > 28, Opera > 47, Safari > 11, Chrome > 21