Ventana was able to identify areas for improvement in its processes

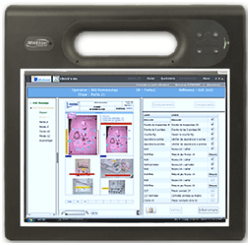

In this short french speaking video, the operator explains how he uses our Qual@xy Suite M.E.S. (Manufacturing Execution System).

Since 2003, VENTANA has a highly developed but also organic way of investing in companies through the complete value chain of its vertical integration strategy. The group now has six companies totalling over 318 years of expertise in the service of high technology.

Using all companies in the group allows them to offer a comprehensive package to customers, ranging from co-design, through to prototyping and production.

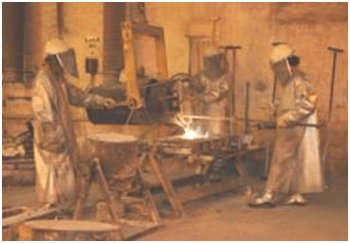

Fonderie MESSIER has patiently developed (over 70 years) unparalleled expertise in the development, industrialisation and production of sand castings precision aluminium and magnesium parts.

Project description

The CARAIBE (Innovative Aeronautical casings for Environmental Profit) is a collaborative project for the development of sand foundry processes which started in late 2010 and was completed in mid-2014 when the resulting new technologies were introduced.

Digital manufacturing development methods were used which resulted in drastically reduced development cycles and industrialisation costs.

However, key to this new design flexibility is reliability and repeatability of the new manufacturing methods.

The CARAIBE project involved several partners, including 3 key integrators (Turbomeca, Airbus Helicopters and Liebherr), SMEs (including Infodream) and various research centres.

The objectives of the project :

- Obtain and implement an efficient computer tool for the statistical monitoring of foundry process data (at all stages)

- Validate process specifications, manufacturing configuration and process recommendations based on the results and data analysis.

Process monitoring using Qual@xy SPC

We focussed on 3 key areas:

- The definition of data: what is relevant? What are the tolerances? How to activate process alerts when the tolerances are exceeded?

- Data acquisition: how is the data recorded and managed? how is the process measured? evaluation of the measurement environment?

- Data processing: what is the most effective way to communicate and present the data? What correlations are there? What statistical analysis or other processing is useful?

The definition of data

The first step was to develop a complete process map of the foundry from incoming material receipt through to final inspection, These included mixing, infiltration, sharps, melting, casting, trimming, NDT inspection, locating.

It was necessary to define a complete chain of data custody starting from the sand and mould mixing (where the actual part does not yet existent) to the casting (creation and identification of the part with real traceability).

Data acquisition

A big step for Infodream was the development of new IT modules and functions. SPC tools already exist, but applying “traditional SPC” methods requires a relatively stable process (by definition, a control chart is statistically relevant only if it follows a stable process) and this was not the case and the foundry!.

Particularly important, was the development of Qual@xy Process software : time management (cycle time, expiry time, process time, etc.), part identification, creation of core kits, etc. Implementation in the field has also been very important: use of hardened computer tablets, WIFI in the workshop with all that this implies in terms of communication disruption, etc.

Data processing

Process data is now regularly monitored, analysed and acted upon and although results are confidential at this stage, the analysis has significantly increased process knowledge and reduced the cost of non-quality.

Summary

This project has generated a considerable change of culture for the foundry: moving from an expert mode (product specialist, diagnosis, compliance) to a monitoring mode over time (statistics, anticipation) is a considerable step.

The provision of work instructions to operators with Qual@xy Process to computer format implies their change in nature :

Work instructions are not only informal:

- Clarification of processes

- Explanation of actions

- Standardisation of procedures

They are binding:

- Obligation to trace actions

- Obligation to plot times, causes of stoppage

Finally, they are « global » and participate in the information system:

- Traceability, horodatage

- Control with Qual@xy SPC

- Monitoring of Work orders (in progress, blocked, etc.)

The deployment of this statistical monitoring and analysis project at Fonderie Messier required a strong involvement of management and supervisors, as well as the willingness to accept certain changes in the organisation. Important cultural changes (IT tools in the workshop, time tracking, time stamping and full traceability) were also triggered by this project.

But it proved that even in a highly operator-dependent environment, with high added value linked to the experience of the people in the field, statistical control and monitoring tools (i.e. the transition from a vision of compliance to a vision of evolution and trends over time) was possible, and made it possible to identify the causes of profound improvement.

This project also advanced the software Qual@xy Process, operational across a complex production chain, including multiple actors and functions.