The key functions of Qualaxy Control

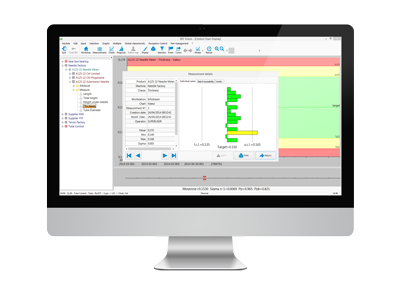

1. Ergonomic data input

A single input screen represents one batch to be inspected. Qualaxy Control (ex-Ctrl Vision) specifies the exact number of parts to be inspected, feature by feature. The correct inspection frequency and sample size is automatically calculated byQualaxy Control.

2. Statistical monitoring of each batch

All Lots are monitored using control charts for each feature. Individual measurement values are stored and used for the calculation of statistical indicators.

3. Powerful parameter configuration

Many parameters within Qualaxy Control can be easily configured by the user including sample size (fixed or variable), releasable variable size, limited variable size, control type, AQL etc.

These can be set up for each product characteristic.

4. Creation of customised standards and configurations

Parameterisation of sizes or percentages of samples, acceptance/rejection criteria, dynamisation.

These in-house standards can be assigned characteristic by characteristic.

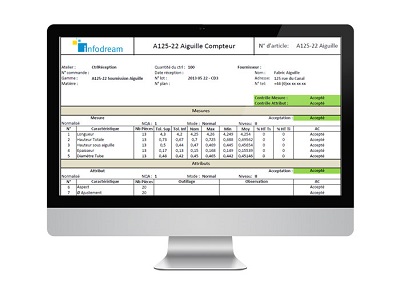

5. Clear and complete reporting

Qualaxy Control “Inspection Report” is completely customizable providing information on both the production batch and supplier. Other new Qualaxy Control features have also been incorporated into the ‘Dashboard’ module.

6. Single database

Like all CT Infodream modules, Qualaxy Control (ex-Ctrl Vision) shares the central ‘Qualaxy’ database including structure and objects. This allows control charts for supplied parts to be viewed alongside SPC charts for internally manufactured products for easy comparison.