Skills Matrix

What are the benefits of managing shopfloor skills & competencies?

Clearly there are regulatory requirements for specific job roles are but there are also other benefits for the operations team. This article will explore what these benefits are and how they can be achieved using Qual@xy MES.

What is skills matrix?

Skills matrix is a function in Qual@xy MES which allows you to manage the skills, authorisations and certifications needed by operators to ensure that the work is carried out by trained personnel.

This can be summarised in 4 questions concerning the operator:

- Does the task require any specific external accreditation (authority)?

- Does the operator have the necessary skills to carry out the specified task?

- Is the operator trained on the machine in which the work takes place?

- Is the operator trained on the product on which they will work?

- Does the operator have the correct habilitation for this work?

A common question is whether such a system should be used to manage the complete factory.

Obviously not, because you would risk falling into these two frequently encountered pitfalls :

- time-consuming day-to-day management

- risks of production stoppage due to a function that is too complex to administer.

This is why, in practice, it is reserved for high value-added operations, which can be estimated at 20% of production.

Skills, authorisations and certifications

Let us now define what skills, authorisations and certification are.

Skills Competence

Competence is the ability to transpose acquired knowledge for the accomplishment of one or more tasks in a particular field.

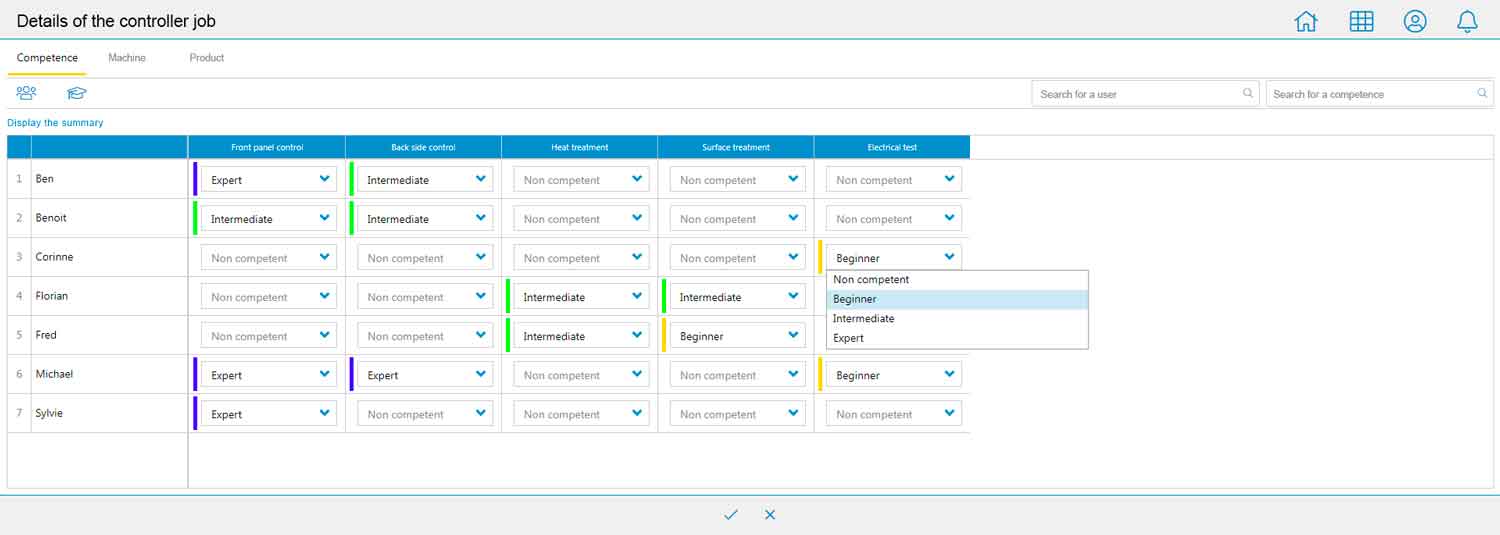

It is a « business » concept, specific to each plant or department. It is often supplemented by a level of competence such as: beginner, intermediate or expert.

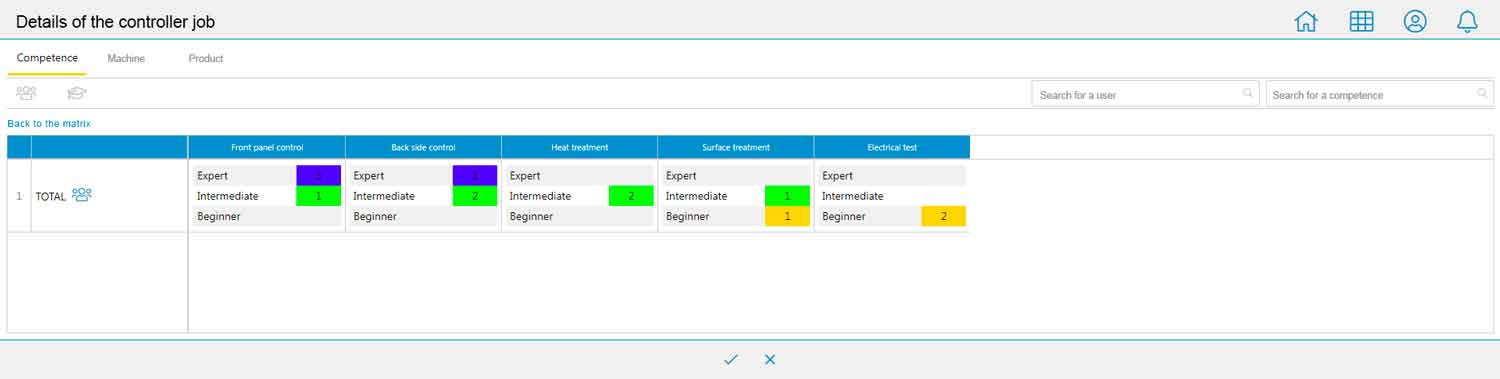

For each operation, the skills matrix displays the number of operators with expert, intermediate or beginner levels.

In industry, skills can be developed through training and mentoring (transfer of know-how).

Authorisation

The authorisation indicates an aptitude and a legal authorisation to carry out an activity in complete safety.

The aptitude is validated by following a training course, both theoretical and practical, and by an individual assessment of the knowledge acquired.

Following an individual assessment, a jury grants legal authorisation – in accordance with the legal texts – to carry out an activity.

The authorisation is often valid for a period of time.

Example of authorisation: Certificate of Operator Safety Competency.

Certification

Certification is a title or diploma awarded by a competent authority (a high authority, an institution or a school).

A vocational certification attests that the holder has acquired, through training and/or work experience, the competences, skills and knowledge necessary for the exercise of a profession.

Certification provides greater professional recognition to the holder.

Examples of qualifications: Youth Training, BTEC, etc.

What are the benefits of skills management?

For the operator

Competence monitoring motivates and values production workers.

As a sign of recognition, a certain loyalty to their employer can be expected. This tends to reduce turnover.

For the manager

In times of crisis, holidays or ramp-up, staff absences are less noticeable because they have less impact on production.

The replacement of absent operators is facilitated by anticipating the necessary operator skills.

For industry

In a highly competitive industrial world, the more competence is developed, the less the industry is threatened.

This is particularly true of new technologies that lead to new behaviours and changes in production processes.

Thus, with the increase in skills, the capacity to adapt also increases.

What are the benefits of managing authorisations and certifications?

For the operator

The management of authorisations and certifications validates skills, both internally and externally. It enhances the value of operators, increases their intrinsic value and therefore their employability.

For the manager

Since the personnel are qualified for the tasks to be performed, the autonomy to carry out the operations increases, and accidents at work decrease.

For industry

The customer is reassured by the certifications held by a supplier. This is a guarantee of the seriousness and quality of the future product delivered.

The supplier, for his part, obtains recognition from his customer. And this generates a climate of mutual respect and trust.

In general, maintaining a high level of competence can be a way of developing mentoring in the company.

It is about an experienced operator sharing their knowledge and experience with a colleague who is new to the job.

Whether we are talking about competences, skills or certifications, they all tend to give more visibility to the human resources department.

For example, when it comes to managing a continuous training plan.

All of these benefits should boost team morale and ultimately improve productivity.

In addition, multi-skilling gives a positive impression of decompartmentalisation of workshops and production areas.

Fears and concerns about multi-skilling

We have just seen that there are many benefits. However, the misuse of skills and competences can lead to disappointmentt.

Indeed, the costs of learning to become more competent can be high in relation to the intended purpose and its actual day-to-day use in the workshop.

The operators present may be called upon to intervene on levels lower than their now recognised level, which may lead to disorganisation and frustration.

Conclusion

Good management of skills, certifications and authorisations therefore has several advantages:

For production operators, it means better visibility on their career. They know their place, their strengths and weaknesses, and what training they need to do to progress. They are also more competitive.

For the HRD and managers, targeting areas for improvement is made easier. Everything is centralised in the same database. They can both modify it according to the departures and arrivals of employees, or their increase in competence.

For the company, it leads to greater efficiency in production management. There are fewer line stoppages, better anticipation, etc.

The company is more serene. The quality of production improves, costs fall and this offers more prospects for everyone.

At a glance, you can see whether an operator is competent to perform an operation, and at what level (beginner, intermediate or expert in this example).

Which tool to use for multi-skilling?

Do you want to digitise your skills processing but don’t know which tool to use?

In the age of Industry 4.0, we can agree that the solution is digital. But will you be satisfied with an Excel file? Will you invest in a dedicated HR solution?

At Infodream, we believe that this is a matter for the production tool, as close as possible to the operators. This is why we have included all the necessary functionalities in our MES solution: the Qualaxy Suite.