The Cost of Non-Quality

Do you have any idea what Non-Quality costs your company?

If so, you are now certainly convinced of the need to monitor this indicator within your quality approach, as it represents a significant source of savings.

If not, this article aims to summarise some of the main methodological concepts for initiating this approach within your company.

The cost of non-quality in French industry

Data from the AFNOR study on the costs of non-quality in industry.

Non-Quality: what are we talking about?

Let’s start at the beginning: here are three ways to define Non-Quality:

1/ For H. J. Harrington, Non-Quality includes :

- Direct » non-quality costs, i.e. those borne directly by the company: control procedures, human resource skills training, product rejects/removals, etc. These types of costs, which are concrete and easily identifiable, are the most easily monitored.

- Indirect » non-quality costs, which are more difficult to measure because they are borne by the customer (damage to image, complaints, etc.)

2/ The AFNOR, through a dedicated study, distinguishes between Non-Quality and Non-Performance: the first refers to product non-conformities, while the second refers to shortcomings linked to the organisation’s management.

3/ Finally, at Infodream, we offer three components of Non-Quality :

- Product non-conformity: characteristics out of tolerance (scratching, tightening torque, etc.)

- Application non-compliance: non-compliance with procedures, unforeseen and damaging workshop events (obsolete tracking form, lack of qualification, etc.)

- Regulatory non-compliance: failure to meet a legal, normative or customer requirement (poorly positioned marking, non-existent traceability field, etc.)

How to measure Non-Quality, and why it is so difficult?

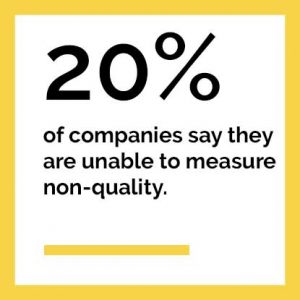

According to AFNOR, while 92% of companies consider it necessary to measure non-quality, 20% of them do not know how to measure it. Beyond the figure itself, the reasons for this obstacle are just as interesting :

- technical difficulties related to the definition of the scope and the choice of indicators

- lack of time to add these new tasks to the existing tasks of the actors concerned

- difficulties in uniting employees around this subject, or even in legitimising it within the company.

The NFX 50-126 standard

Despite these difficulties, the NFX-50-126 standard proposes a methodology for detecting and calculating the costs linked to non-quality. Although a little old, its guidelines are still relevant today for identifying cost items :

- Costs of internal anomalies, linked to product quality defects during the manufacturing process (scrap, rework, defective raw material, absenteeism, etc.)

- Costs of external anomalies, linked to product quality defects as a result of the manufacturing process (complaints, penalties, refunds, etc.)

- Detection costs, linked to the verification of product conformity (payroll dedicated to controls, depreciation of equipment, dedicated subcontracting, etc.)

- Prevention costs, linked to the continuous improvement process (supplier evaluation, audits, dedicated administrative workload, etc.)

Finally, how much does it cost me?

The question of the cost of this non-quality is essential, especially for companies that have not yet initiated this evaluation process.

Obviously, the results can be very different from one company to another.

Nevertheless, here are three key ideas to keep in mind on this aspect:

1/ Estimated order of magnitude:

- The first studies on the subject (dating from 1986) indicate a minimum cost of 2,500 euros per year per employee.

- Then, in 1991, the Mouvement Français pour la Qualité (French Movement for Quality) estimated the costs of Non-Quality to be around 15% of companies’ turnover.

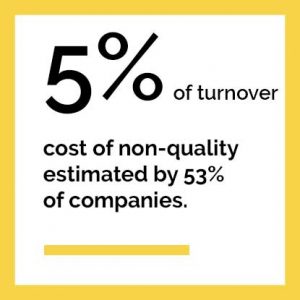

- Nowadays, the AFNOR study reveals that for 53% of companies, the cost of non-quality is between 1 and 5% of turnover (for 34% of them, this cost amounts to more than 5% or even more than 10%).

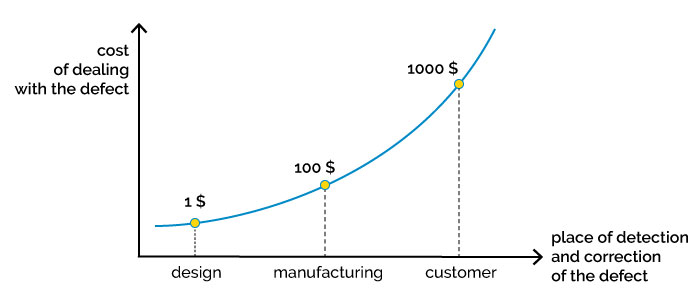

2/ Costs according to the phase of detection: another method of evaluation consists in dividing them according to the phase during which the anomalies are detected. According to Guy Couturier, the cost is:

- 1 € if the defect is detected during the design phase

- 100 € if the defect is detected during the manufacturing phase

- 1000 € if the anomaly is detected by the customer

- And how much in case of an accident?

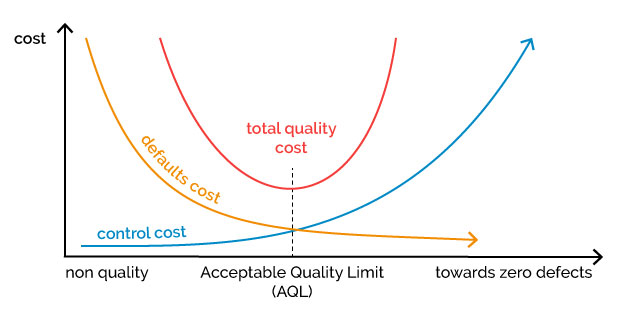

3/ Finally, it is wise to seek to prioritise improvement actions rather than to eradicate defects completely. Indeed, the human, organisational and financial efforts required are probably too high in relation to the additional benefits obtained by a prioritisation approach.

To get started

If you are now convinced that it is in your company’s interest to initiate a Non-Quality assessment process, here are some ideas for identifying the information required:

- look in the general or analytical accounts (purchases of raw materials, supplies, payroll, etc.)

- check administrative, technical or commercial documents (non-conformity reports, rejected quantities, follow-up of customer complaints, etc.)

- ask, through the organisation of surveys or direct questioning of knowledgeable staff.

But also and above all, rather than suffering the costs of this non-quality, have you ever thought of looking upstream in order to avoid its appearance? Indeed, solutions exist to monitor, manage and control your industrial process:

- MES (Manufacturing Execution System): it allows, among other things, the digitisation of tracking sheets;

- SPC (Statistical Process Control), ensures the control of your production for real-time detection of drifts (anticipation of manufacturing defects);

- Dashboards, to help you visually manage the performance of your workshops.

Sources

- AFNOR survey, The costs of non-quality in industry (October 2017)

- Blog of Guy COUTURIER MC Management

- H. J. Harrington, Le cout de la non-qualité Ed. Eyrolles (January 1990)

Florian Cassin

Sales Engineer, CT Infodream

You may also be interested in this article…

Reduce your non-conformities thanks to MES

Non-conformity, defect, rejection, anomaly... whatever the name, it's always a production nightmare. Whether it is critical, major or minor, non-conformity must be dealt with before it impacts the production. And the M.E.S. is a formidable tool for this. No, anomalies,…