Your challenges and constraints

– Small series with high added value

– Compliance with NADCAP, EN/AS9100, SC21 standards

– Conservation of production data

– Identification of the root causes of drift

– Follow-up of rework

– Management of long and complex processes

– Scalability of processes

Functions to discover

– Complete traceability at three levels

– Exhaustive follow-up of manufacturing data

– Monitoring of production, waiting and interruption times

– Synchronisation with ERP

– Identification and monitoring of production hazards

– Versioning and workflow validation

They trust us

Airbus, Safran, Thales, Mecachrome, Dassault, Fly by Wire, Europropulsion, etc.

Learn more

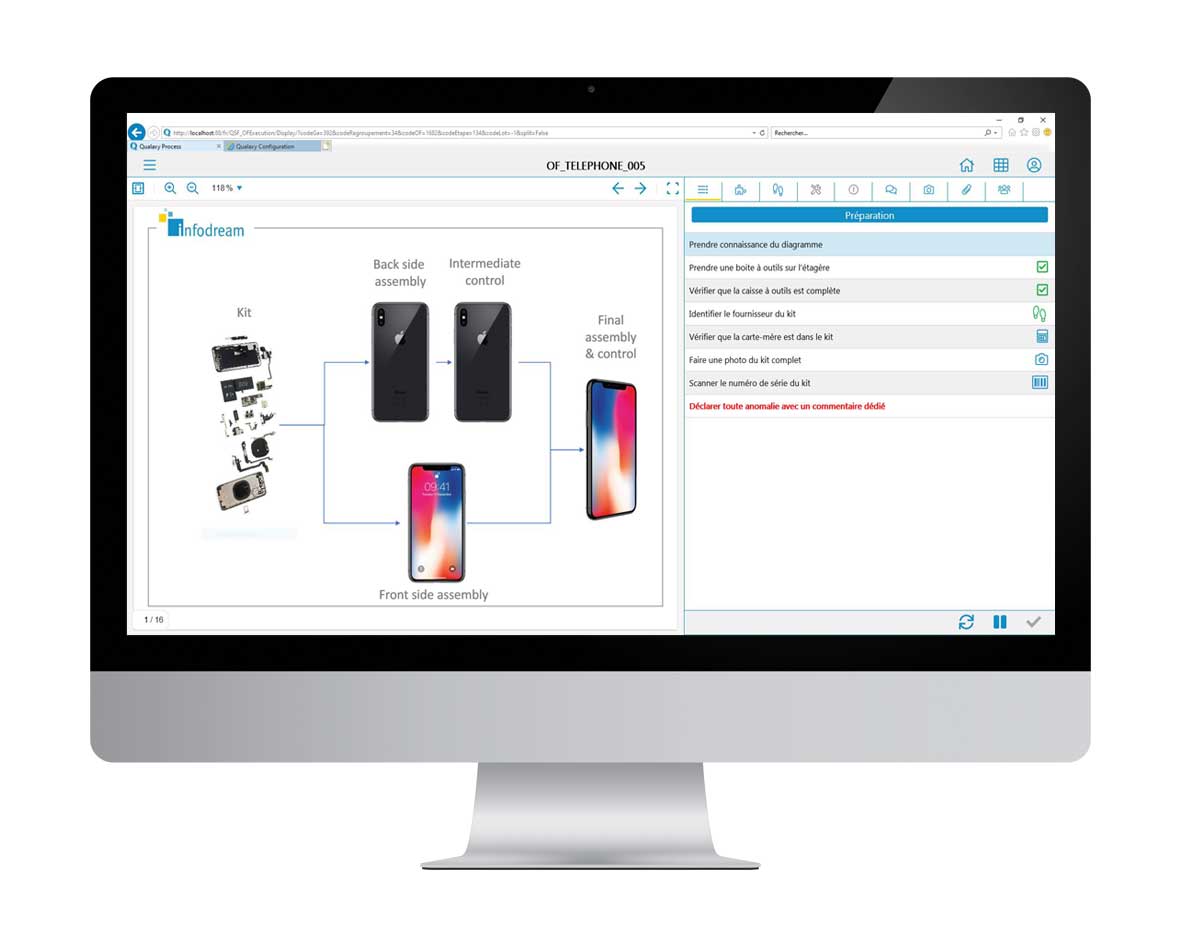

Customers have naturally turned to Infodream for workshop management.

Discover a flexible and comprehensive solution, ideal for complex industrial processes.

Features

SPC monitoring: workshop steering through quality

- real-time alarms

- ensure stable quality

- traceability and rework

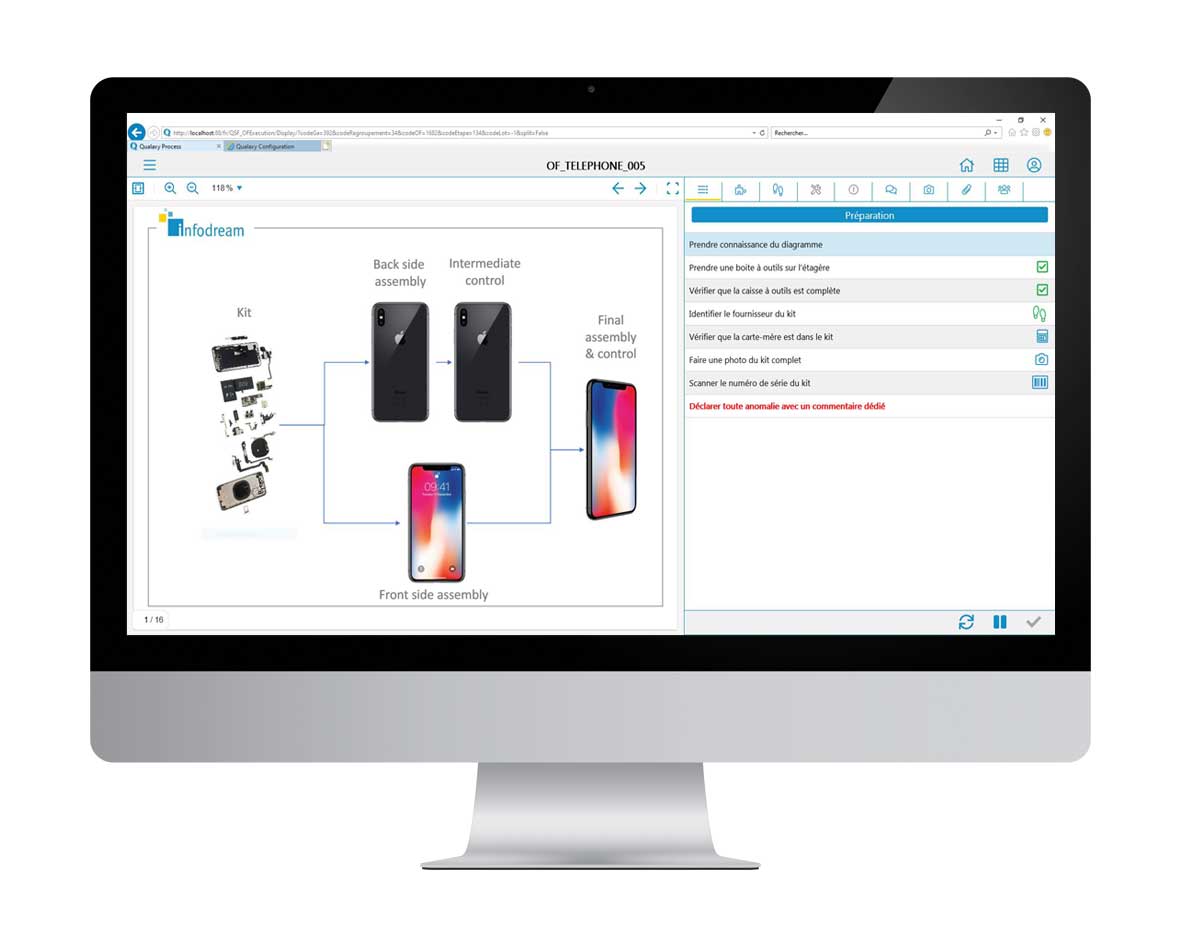

The progress of WOs in the workshop

- operator guidance

- follow-up of the manufacturing data

- synchronisation with your management tools

Visualisation of workshop performance

Advanced functions

- genealogy of your parts or products

- follow-up of non-conformities

- monitoring of qualifications and skills

- versioning

They trust us

We are the European leader in this industry.

Infodream is a member of the Gifas & Aerospace Cluster of Rhône-Alpes.

Your challenges and constraints

– Small series with high added value

– Compliance with NADCAP, EN/AS9100, SC21 standards

– Conservation of production data

– Identification of the root causes of drift

– Follow-up of rework

– Management of long and complex processes

– Scalability of processes

Functions to discover

– Complete traceability at three levels

– Exhaustive follow-up of manufacturing data

– Monitoring of production, waiting and interruption times

– Synchronisation with ERP

– Identification and monitoring of production hazards

– Versioning and workflow validation

They trust us

Airbus, Safran, Thales, Mecachrome, Dassault, Fly by Wire, Europropulsion, etc.

Learn more

Customers have naturally turned to Infodream for workshop management.

Discover a flexible and comprehensive solution, ideal for complex industrial processes.

Features

SPC monitoring: workshop steering through quality

- real-time alarms

- ensure stable quality

- traceability and rework

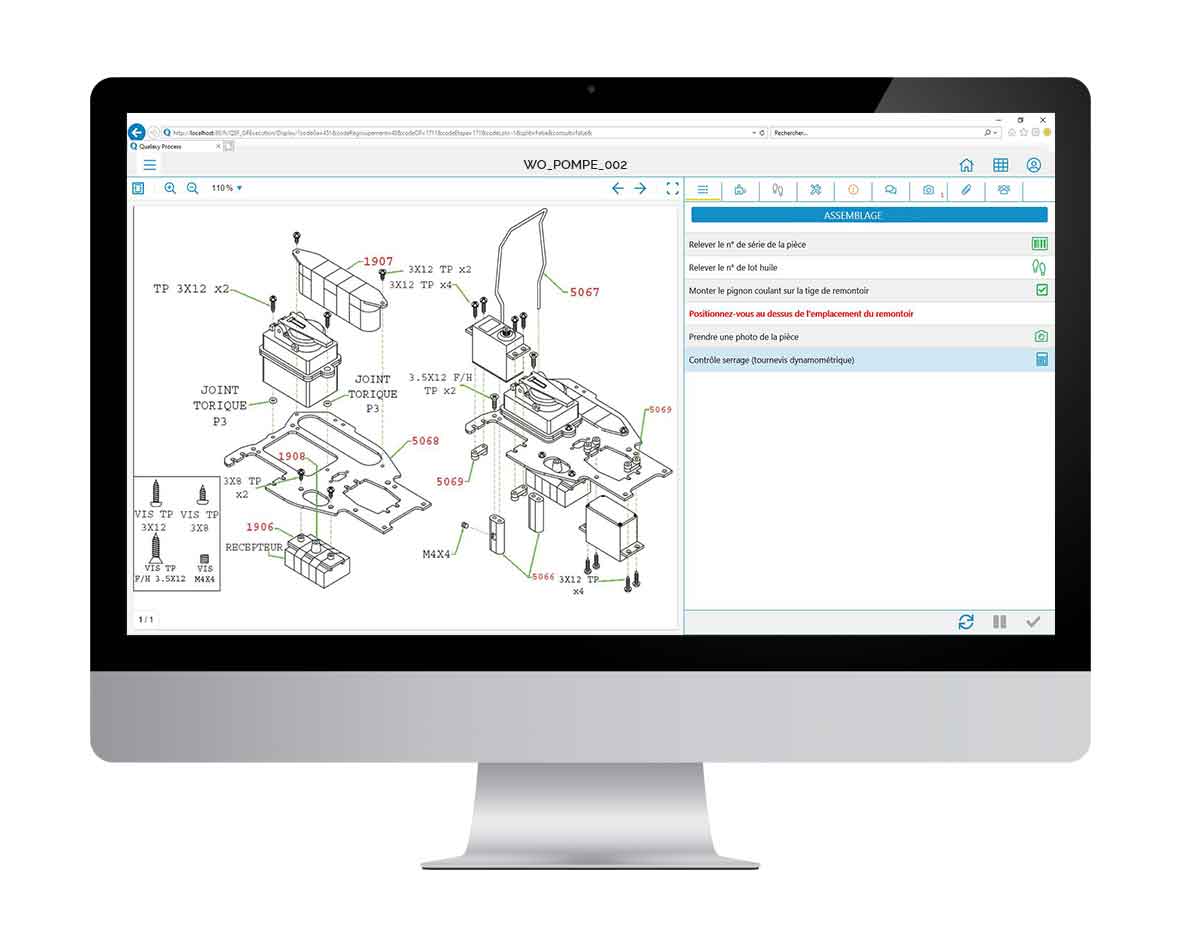

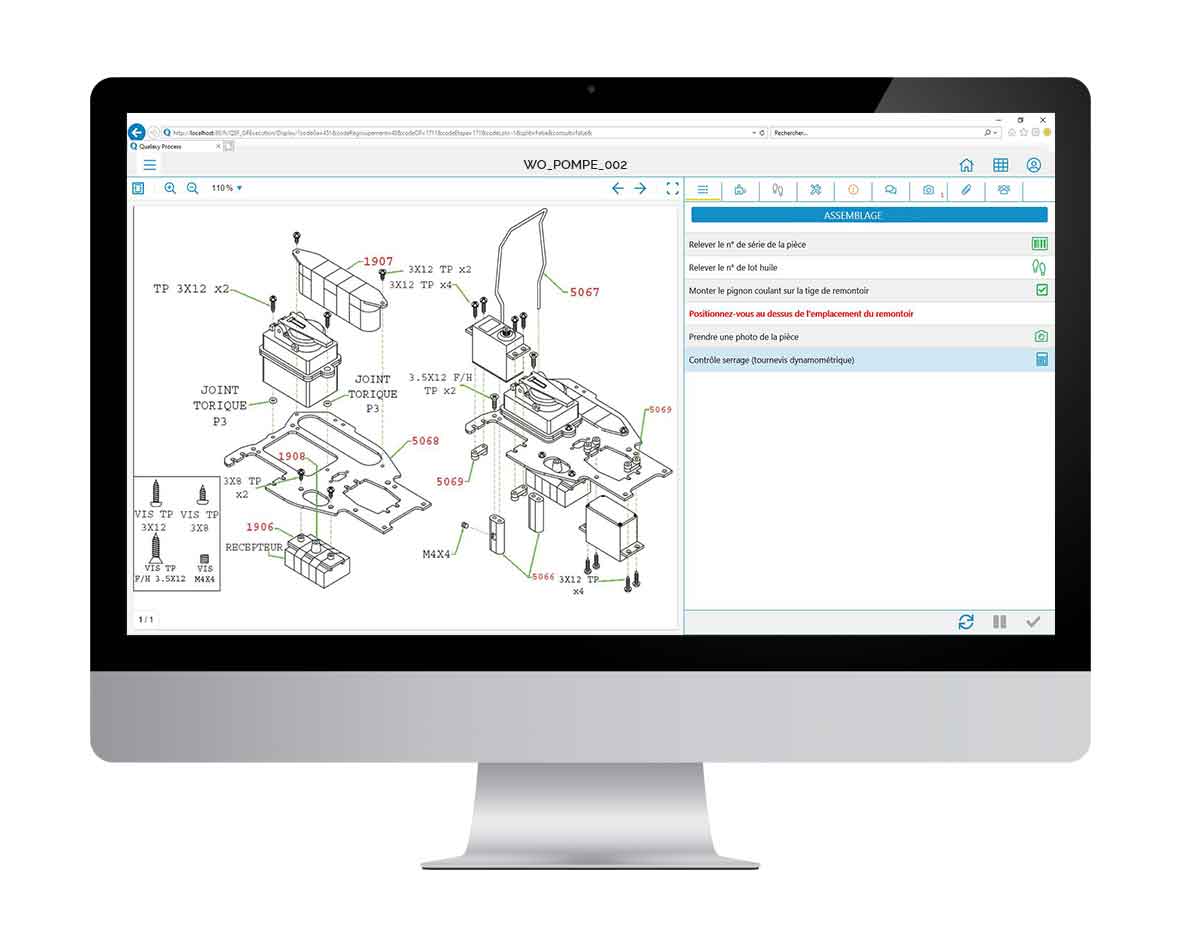

The progress of WOs in the workshop

- operator guidance

- follow-up of the manufacturing data

- synchronisation with your management tools

Visualisation of workshop performance

Advanced functions

- genealogy of your parts or products

- follow-up of non-conformities

- monitoring of qualifications and skills

- versioning

They trust us

We are the European leader in this industry.

Infodream is a member of the Gifas & Aerospace Cluster of Rhône-Alpes.

Your challenges and constraints

– Large series production

– Conformity: CNOMO, ISO TS,ISO TS 16 949, MSA

– Real-time measurement management

– Control by sampling, modulation

– Continuous improvement, help in detecting root causes

Functions to discover

– Complete traceability and genealogy

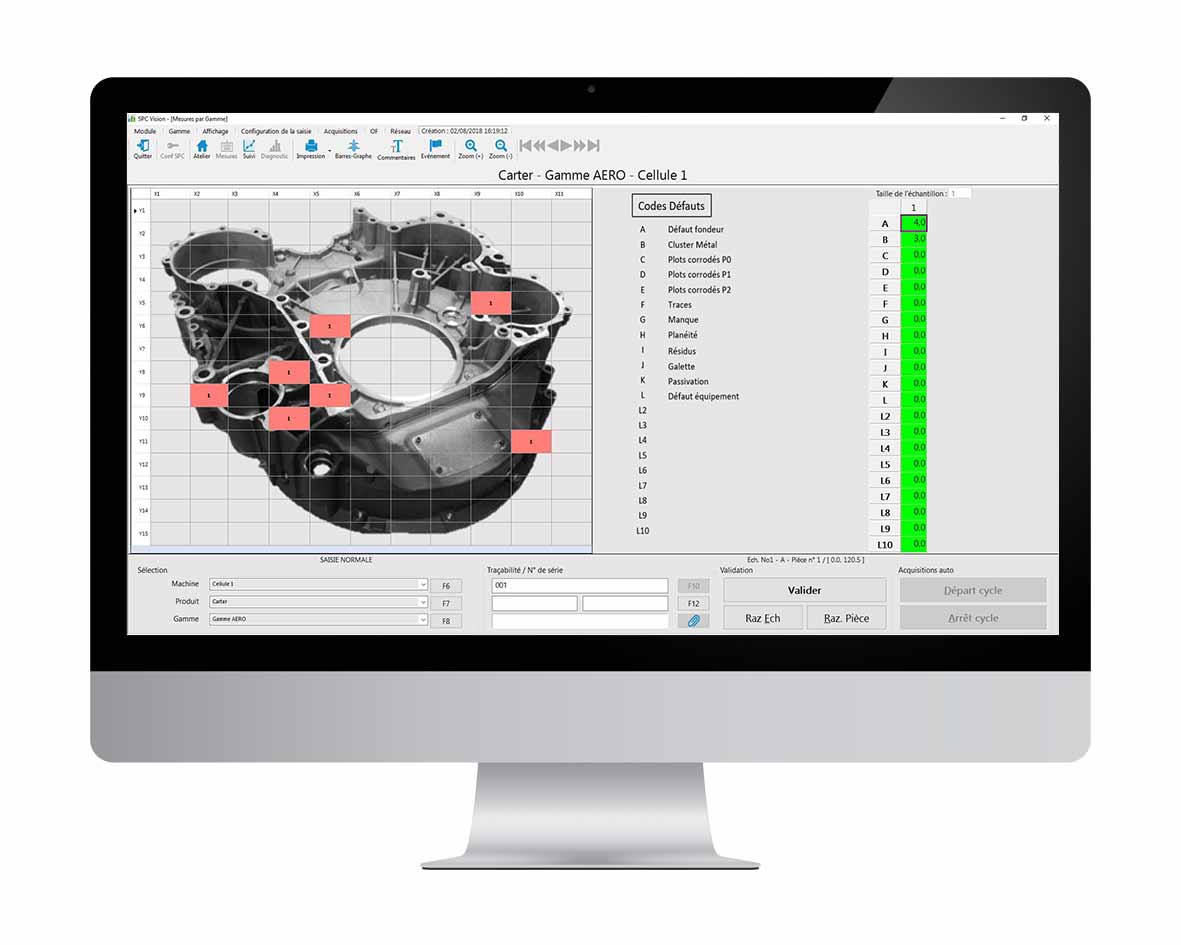

– Graphical analysis of global characteristics & multiple charts

– Quality module, real-time SPC monitoring

– Reduced waste, lighter controls

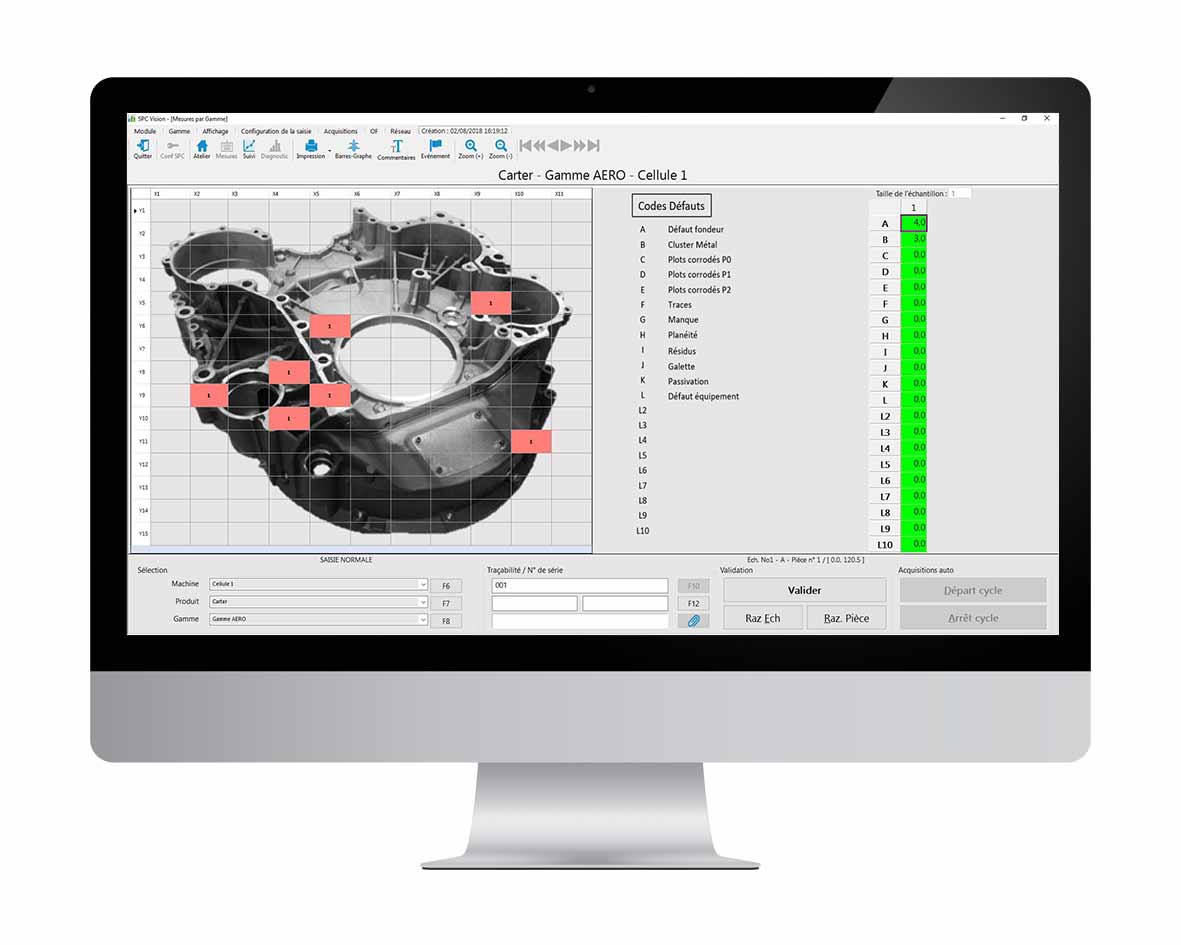

– Location and mapping of defects

They trust us

Stellantis, Aptiv, Favi, Mecachrome, and many others.

Learn more

Features

Qual@xy SPC, a key tool for the automotive industry

- sampling plan and compliance with standards

- anticipation of drifts

- functional coverage of the entire production line

- fault location and removal of root causes: Defect Map function

Qual@xy Process, the operator interface

- electronic work instructions

- recording of measurements and traceability

Qual@xy Dashboard and Cockpit

- real-time steering and medium to long-term analysis

- Identification of areas for requiring improvement

- customised report generation

- integrated datamining

Advanced function

Monitoring of tools.

They trust us

Your challenges and constraints

– Large series production

– Conformity: CNOMO, ISO TS,ISO TS 16 949, MSA

– Real-time measurement management

– Control by sampling, modulation

– Continuous improvement, help in detecting root causes

Functions to discover

– Complete traceability and genealogy

– Graphical analysis of global characteristics & multiple charts

– Quality module, real-time SPC monitoring

– Reduced waste, lighter controls

– Location and mapping of defects

They trust us

Stellantis, Aptiv, Favi, Mecachrome, and many others.

Learn more

Features

Qual@xy SPC, a key tool for the automotive industry

- sampling plan and compliance with standards

- anticipation of drifts

- functional coverage of the entire production line

- fault location and removal of root causes: Defect Map function

Qual@xy Process, the operator interface

- electronic work instructions

- recording of measurements and traceability

Qual@xy Dashboard and Cockpit

- real-time steering and medium to long-term analysis

- Identification of areas for requiring improvement

- customised report generation

- integrated datamining

Advanced function

Monitoring of tools.

They trust us

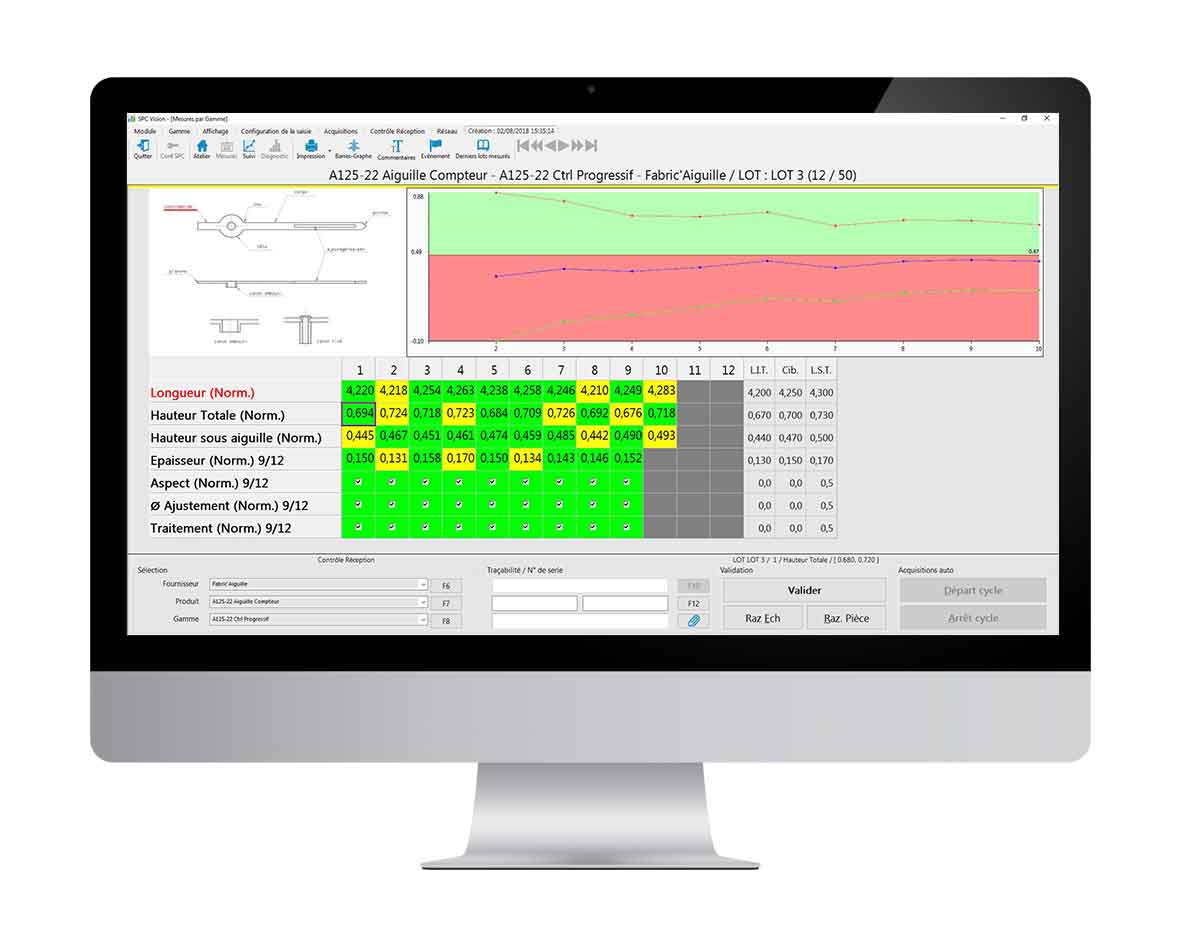

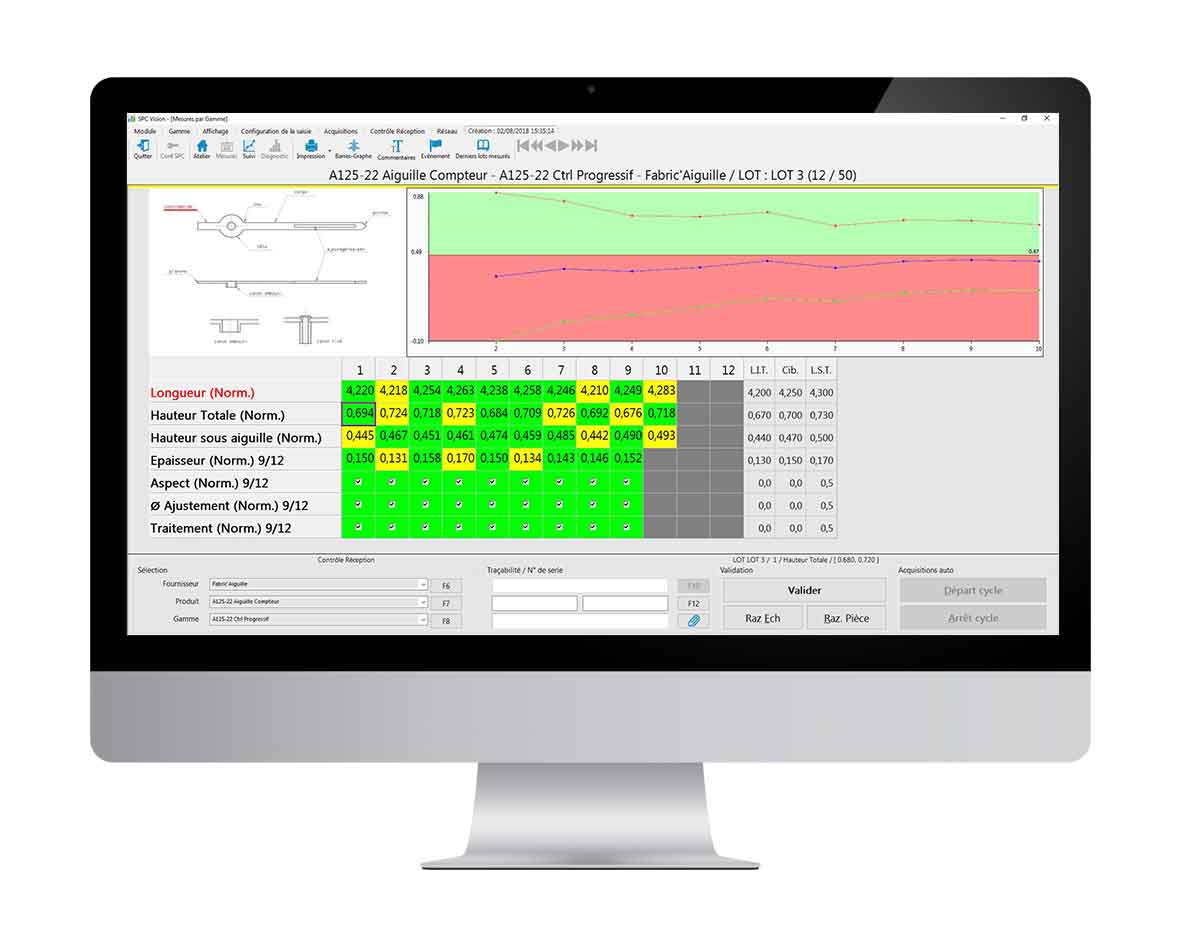

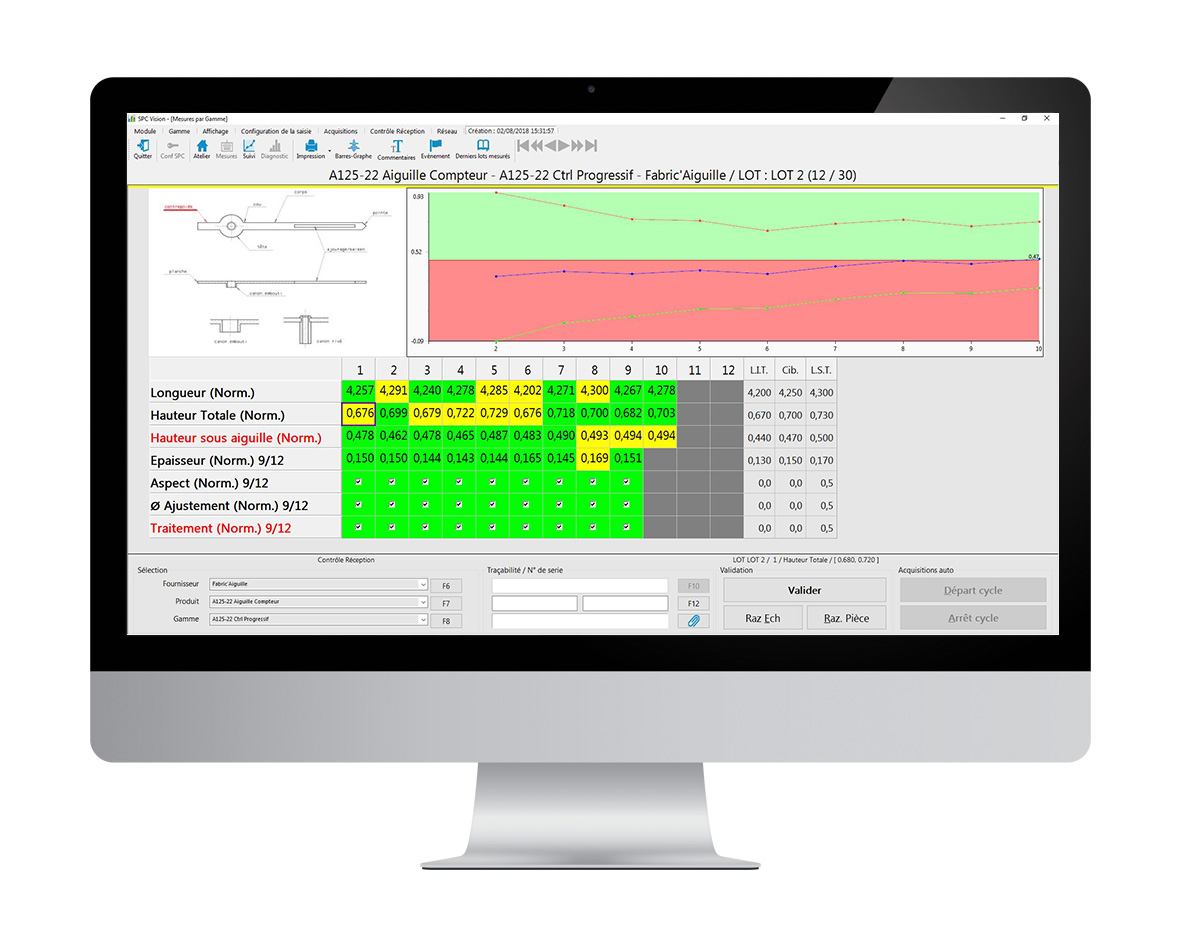

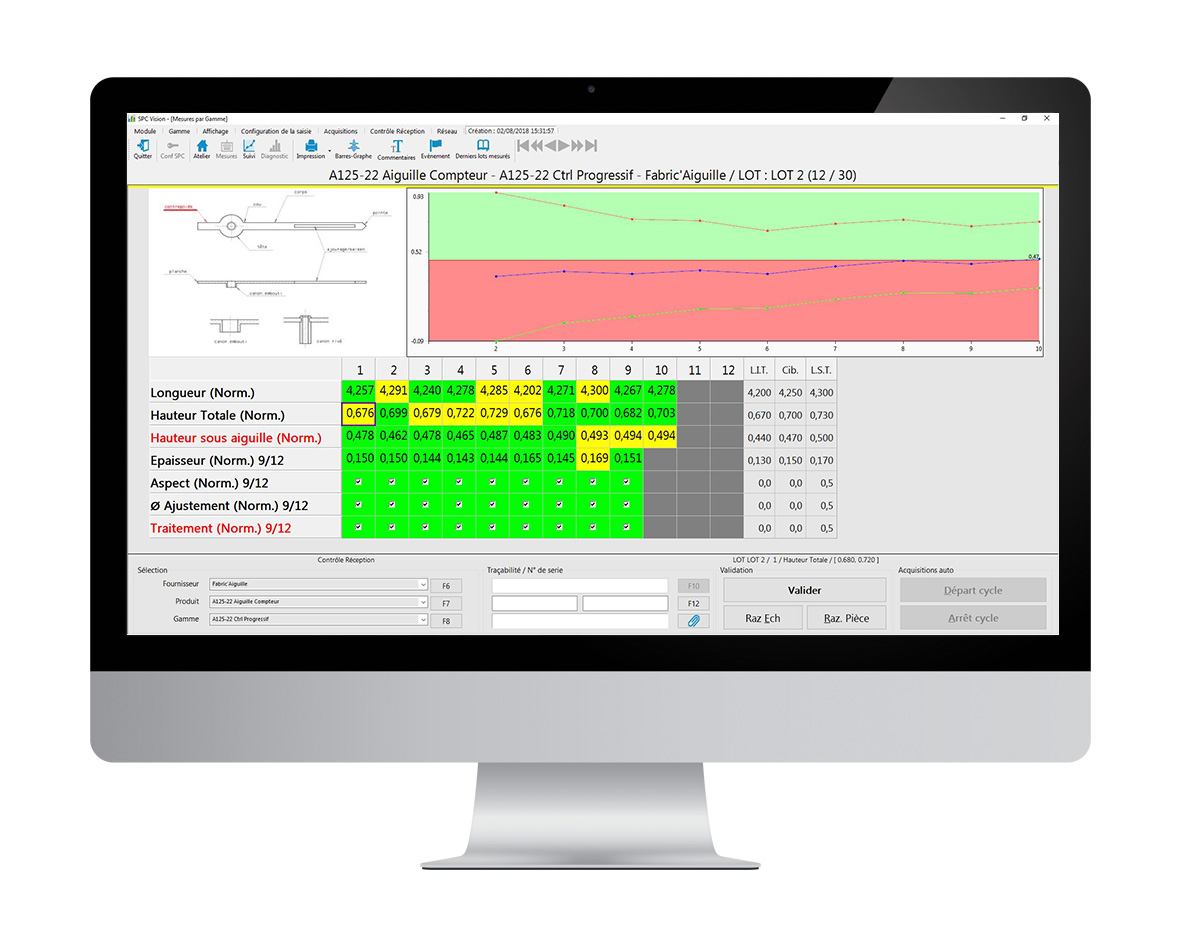

Your challenges and constraints

– Small and medium series production

– Compliance: ISO 2859 and 3951, progressive ctrl and in-house standards

– Adjustment of complex processes

– Machining of high-precision parts with tight tolerances

– Meticulous assembly

Functions to discover

– Incoming control, monitoring of batch acceptance

– Matrix control, the help to the machine setters

– Real-time monitoring of production measurements

– Inertial tolerance

They trust us

We accompany major Haute-Horlogerie brands.

Lear more

Features

Qual@xy Control

- conformity of parts

- acceptance of batches and AQLs

- real-time SPC monitoring

- matrix control

- inertial tolerancing

Qual@xy Process, the operator interface

- electronic work instructions

- recording of measurements and traceability

Advanced function

Notifications

You are notified of any event (stoppage, out-of-tolerance measurement, etc. on your manufacturing process).

Your challenges and constraints

– Small and medium series production

– Compliance: ISO 2859 and 3951, progressive ctrl and in-house standards

– Adjustment of complex processes

– Machining of high-precision parts with tight tolerances

– Meticulous assembly

Functions to discover

– Incoming control, monitoring of batch acceptance

– Matrix control, the help to the machine setters

– Real-time monitoring of production measurements

– Inertial tolerance

They trust us

We accompany major Haute-Horlogerie brands.

En savoir +

Features

Qual@xy Control

- conformity of parts

- acceptance of batches and AQLs

- real-time SPC monitoring

- matrix control

- inertial tolerancing

Qual@xy Process, the operator interface

- electronic work instructions

- recording of measurements and traceability

Advanced function

Notifications

You are notified of any event (stoppage, out-of-tolerance measurement, etc. on your manufacturing process).

Your challenges and constraints

– Mainly automated production

– Compliance: FDA CFR 21 Part II, GAMP 5, PAT, ISO 13485

– Product and process validation

– Securing access to workstations

Functions to discover

– Consolidate production and laboratory controls

– Workflow validation, time stamp, electronic signature

– Monitoring of qualifications and skills

– Data collection and electronic signatures

They trust us

Mölnlycke Health Care, Macopharma, Fresenius Kabi, Novasep and many others.

Learn more

Features

Qual@xy Process, the operator interface

- electronic work instructions

- monitoring of qualifications and skills

- full traceability

Qual@xy Control

- acceptance of batches and AQLs

- real-time SPC monitoring

- conformity of parts

Advanced function

Subdivision.

They trust us

Your challenges and constraints

– Mainly automated production

– Compliance: FDA CFR 21 Part II, GAMP 5, PAT, ISO 13485

– Product and process validation

– Securing access to workstations

Functions to discover

– Consolidate production and laboratory controls

– Workflow validation, time stamp, electronic signature

– Monitoring of qualifications and skills

– Data collection and electronic signatures

They trust us

Mölnlycke Health Care, Macopharma, Fresenius Kabi, Novasep and many others.

Learn more

Features

Qual@xy Process, the operator interface

- electronic work instructions

- monitoring of qualifications and skills

- full traceability

Qual@xy Control

- acceptance of batches and AQLs

- real-time SPC monitoring

- conformity of parts

Advanced function

Subdivision.

They trust us

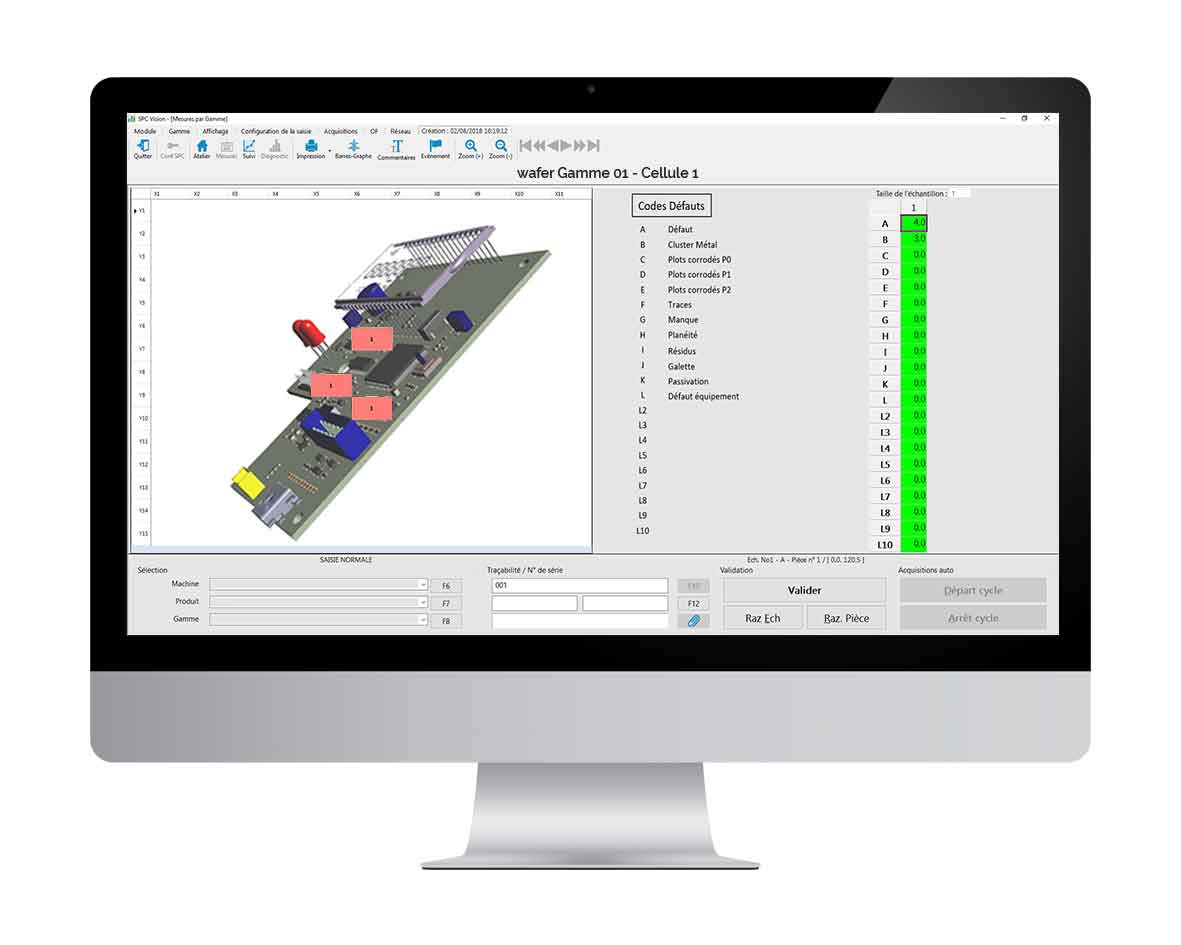

Your challenges and constraints

– Mainly automated production

– Supervision of critical parameters

– Non-destructive testing

– Zero paper workshop (imperative in clean room)

– Connection to machines

Functions to discover

– Correlate your product and process parameters

– Digitise your processes

– Map the defects

– Anticipate the drifts of your production tools with SPC

– Connect directly to the test benches

They trust us

Safran, Tronics, Thales, Lynred, Radiall, and many others.

Learn more

Features

Qual@xy Process, the operator interface

- electronic work instructions

- monitoring of qualifications and skills

- full traceability

Qual@xy SPC

- monitoring of product characteristics and process parameters

- Defect mapping and removal of root causes with the Defect map function

Advanced functions

- delegation (subcontracting of an operation to a third party application)

- parallelization of operations

They trust us

Your challenges and constraints

– Mainly automated production

– Supervision of critical parameters

– Non-destructive testing

– Zero paper workshop (imperative in clean room)

– Connection to machines

Functions to discover

– Correlate your product and process parameters

– Digitise your processes

– Map the defects

– Anticipate the drifts of your production tools with SPC

– Connect directly to the test benches

They trust us

Safran, Tronics, Thales, Lynred, Radiall, and many others.

Learn more

Features

Qual@xy Process, the operator interface

- electronic work instructions

- monitoring of qualifications and skills

- full traceability

Qual@xy SPC

- monitoring of product characteristics and process parameters

- Defect mapping and removal of root causes with the Defect map function

Advanced functions

- delegation (subcontracting of an operation to a third party application)

- parallelization of operations

They trust us

Your challenges and constraints

– All types of production

– Adaptable solution to the existing industrial environment

– Scalable solution

Functions to discover

– Customised parameterisation

– Quality management

– Compliance with manufacturing procedures

– KPI, performance analysis

– Family process

They trust us

BIC, Groupe SEB, Vaillant Group, Radiall, etc.

Learn more

They trust us

Your challenges and constraints

– All types of production

– Adaptable solution to the existing industrial environment

– Scalable solution

Functions to discover

– Customised parameterisation

– Quality management

– Compliance with manufacturing procedures

– KPI, performance analysis

– Family process

They trust us

BIC, Groupe SEB, Vaillant Group, Radiall, etc.

En savoir +

They trust us