Quality control software

Quality control software for industry

Control the quality of parts or batches in your workshop

BEFORE (raw materials, components, etc.), THROUGHOUT and AFTER production (liberating control).

Our Industry 4.0 solution is developed by Infodream in Aix-les-Bains (France), by our team of developers and experts in quality and statistics.

Our philosophy is to be close and attentive to our industrial clients.

They are true partners because they actively participate in the evolution of our software suite.

The quality control software created and developed by Infodream is an innovative M.E.S: Qualaxy Suite.

SUPPORT TEAM

The responsiveness of our hotline technicians is regularly praised by our customers.

We guarantee an adapted and personalised response, without delay, at any time of the day.

EVOLUTIVENESS

Our quality software is the best on the market.

Our strength is to make them evolve to constantly adapt to the needs of our customers.

ADAPTABILITY

The connection to an ERP, to machines or to any other connected work tool is a recurrent demand to which we know perfectly how to respond.

2 RELEASES A YEAR

New functionalities are developed to be useful to as many people as possible…

and are sent twice a year to our customers, free of charge, on request.

Infodream develops its quality control software

for all industry sectors

AUTOMOBILE

Traceability and genealogy, graphical analysis of global characteristics & multiple maps, quality module, real-time SPC tracking, scrap reduction, inspection relief, defect location and mapping…

CLOCK MAKING

Major manufacturers trust us in the Haute Horlogerie sector.

Infodream supports them in optimising costs and improving quality.

HEALTH

Our software is used by Novasep, Mölnlycke Health Care, Macopharma, Fresenius Kabi, and many others.

We have the best tools for traceability and compliance in this very demanding sector.

AEROSPACE

Our software is appreciated by the biggest names in aeronautics (Airbus, Dassault Aviation, Safran, etc.) for its robustness, its response to industry standards for traceability and its ease of configuration.

ELECTRONIC & DEFENSE

Infrared sensors, printed circuits, electronic boards, etc.

Our M.E.S software and its SPC (Statistical Process Control) module are used by our customers to manufacture these micro-mechanisms.

OTHER INDUSTRIES

Whatever your industry, our solution adapts to your needs: paperless workshop, SPC monitoring, supplier batch control or KPI display.

The Qualaxy Suite: a packaged and turnkey M.E.S solution

The functions of our quality control software :

Measurement management

SPC Alarms

Defect Mapping

Supplier quality control

Integrated reporting and statistical analysis

Interactive work instructions

Traceability

Performance analysis

Quality and productivity dashboards

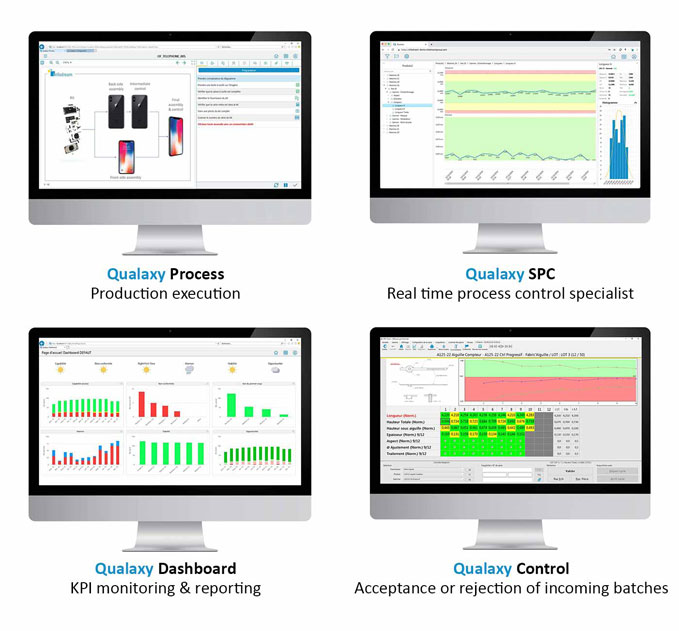

The 4 modules of our quality control software

Qualaxy Control

to control the quality of supplier batches, and the release control.

Qualaxy Process

to digitise operating procedures and guide operators in their daily tasks.

Qualaxy SPC

quality with real-time SPC (statistical process control).

Qualaxy Dashboard

for displaying quality and productivity indicators (KPI).

They trust us

These customer case studies should interest you…

Safran Ceramics makes production more reliable with CT Infodream’s M.E.S.

Who is Safran Ceramics ? Safran's centre of excellence for high-temperature composite materials, Safran Ceramics is a strategic centre for…

Ventana was able to identify areas for improvement in its processes

In this short french speaking video, the operator explains how he uses our Qual@xy Suite M.E.S. (Manufacturing Execution System).

Airbus Helicopters case study

I was instantly attracted by the end user simplicity and easy implementation of Qualaxy Process. Eric Galanakis Production Manager Qual@xy…